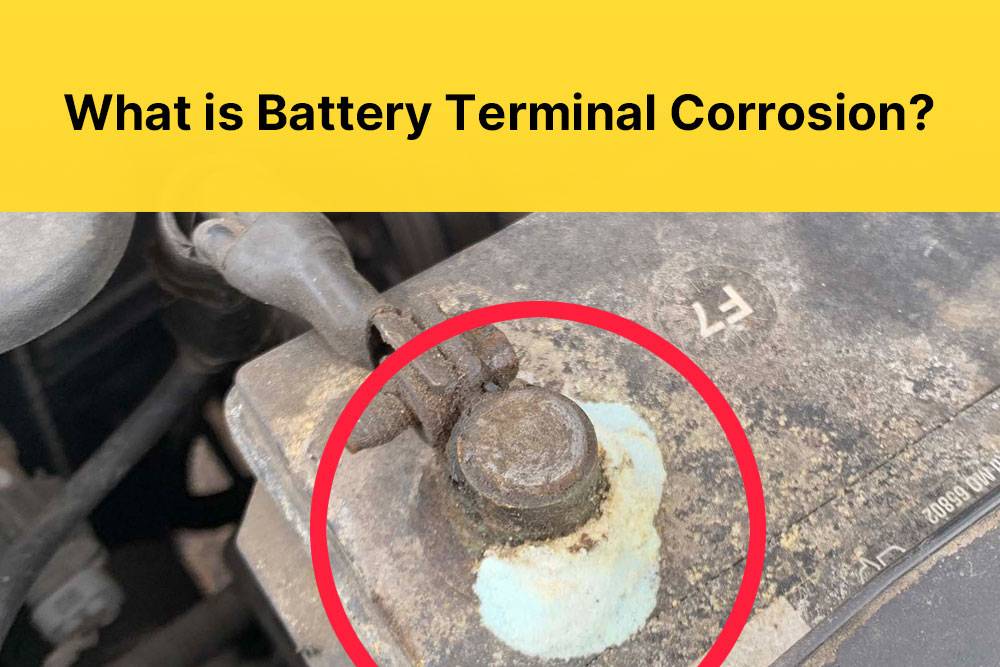

Battery terminal corrosion is a common issue faced by many vehicle and electronic device owners, often resulting in poor electrical connections and device malfunctions. Understanding the causes of battery corrosion and implementing preventive measures is crucial to maintaining the reliability and longevity of batteries and associated electrical systems.

What is Battery Terminal Corrosion?

Battery terminal corrosion refers to the accumulation of corrosive material, often appearing as a white, powdery substance, around the terminals of a battery. This corrosion occurs due to chemical reactions between the battery acid and the metal terminals, which are accelerated by factors such as moisture, heat, and contaminants in the air. Over time, battery terminal corrosion can hinder the flow of electricity between the battery and connected devices, potentially leading to poor electrical connections, voltage drops, and malfunctioning electronic systems.

Battery Terminal Corrosion and Lead-acid Battery

Battery terminal corrosion primarily affects lead-acid batteries due to the chemical reactions between the battery acid and the metal terminals. However, other types of batteries, such as nickel-cadmium and nickel-metal hydride batteries, may also experience corrosion to some extent, although it is less common compared to lead-acid batteries. Additionally, newer battery technologies like lithium-ion batteries are less prone to terminal corrosion because they do not produce corrosive gases during charging.

What Causes Battery Terminal Corrosion?

Battery terminal corrosion poses a significant threat to the performance and longevity of lead-acid batteries. Understanding the causes and consequences of this issue is crucial for maintaining battery health and safety.

- Chemical Reaction: Corrosion occurs when battery acid reacts with the metal terminals, typically made of lead, due to exposure to moisture, heat, and airborne contaminants.

- Environmental Factors: Factors such as overcharging or undercharging the battery, as well as excessive water during maintenance, can accelerate corrosion by facilitating electrolyte leakage and gas release.

- Visible Signs: Corrosion manifests as visible deposits on battery terminals, indicating the escape of hazardous gases and posing risks to both battery functionality and personal safety.

By recognizing the causes of battery terminal corrosion and implementing preventative measures, such as using high-quality lithium batteries, users can ensure safer and more reliable battery operation, minimizing the risk of damage and maximizing battery lifespan.

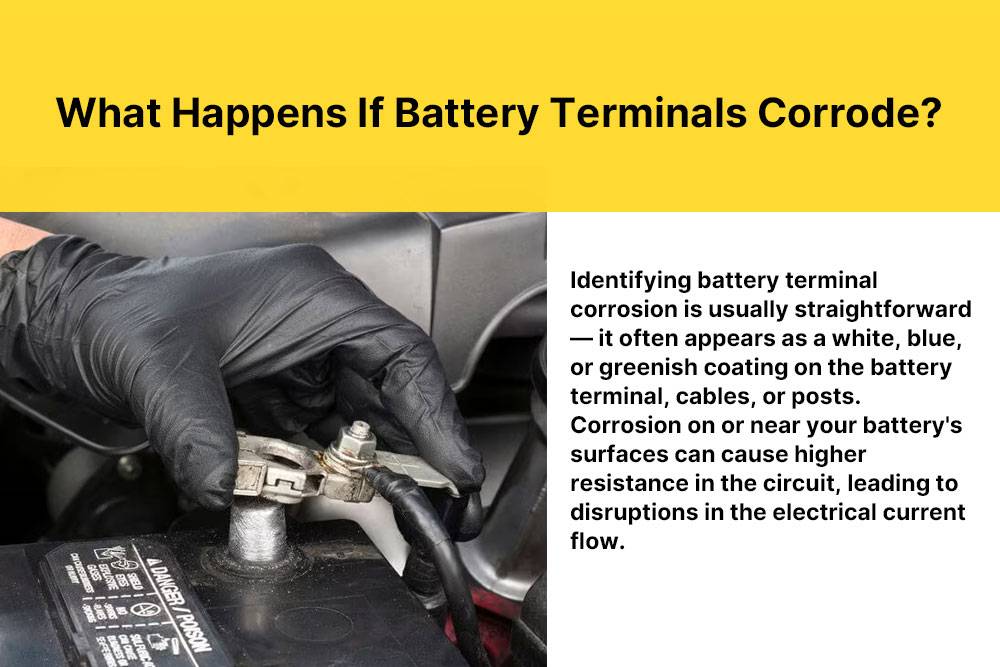

What Happens If Battery Terminals Corrode?

Battery terminal corrosion can have significant impacts on the performance of electrical systems. Understanding the consequences of corroded terminals is essential for effective maintenance and troubleshooting.

- Electrical Impedance: Corrosion obstructs the smooth flow of electricity between the battery terminals and connected devices, resulting in poor electrical connections and voltage drops.

- Reduced Power Output: The presence of corrosion decreases the efficiency of power transfer from the battery to the device, leading to diminished performance and potentially preventing the device or vehicle from starting.

- Risk of Overheating: In severe cases, corroded terminals may cause excessive resistance, leading to overheating during high-current draw situations, which can damage cables and batteries.

Corrosion on battery terminals not only hampers electrical conductivity but also poses risks of reduced power output, potential device malfunction, and overheating hazards. Regular maintenance and cleaning of terminals are essential to mitigate these issues and ensure optimal battery performance.

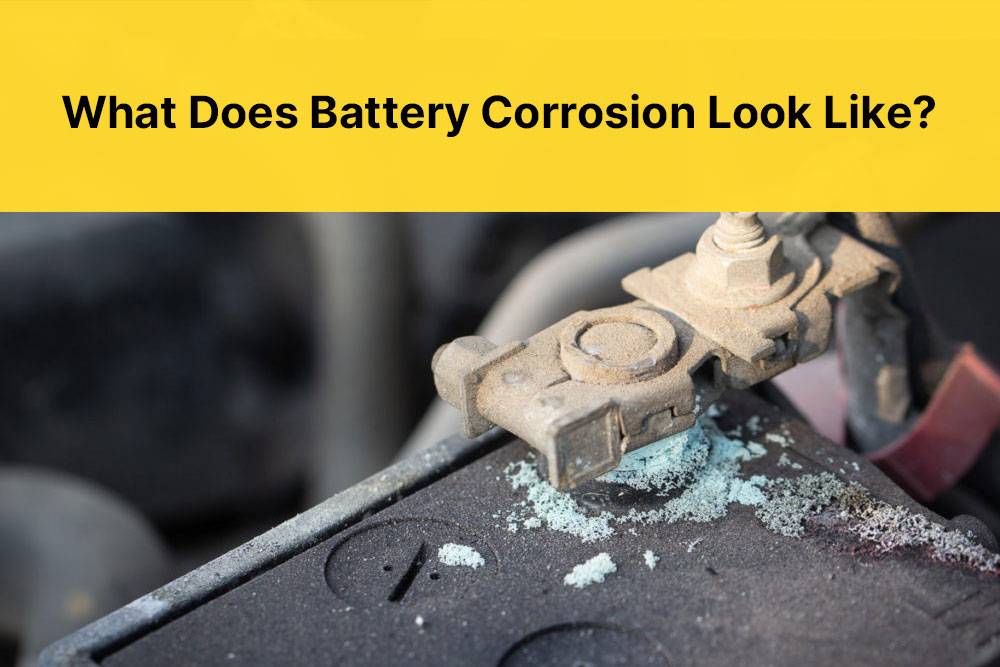

What Does Battery Corrosion Look Like?

Recognizing battery corrosion is crucial for maintaining the health of your electrical system. Knowing what to look for can help you identify and address potential issues before they escalate.

- White, Powdery Substance: Battery corrosion often presents as a white, powdery substance around the terminals, indicating a chemical reaction between the battery acid and metal terminals.

- Greenish or Bluish Deposits: In some instances, corrosion may appear as greenish or bluish deposits on the terminals, signaling a more advanced stage of deterioration.

- Variety of Colors: The color of corrosion can vary depending on the type of battery and the materials involved, ranging from white to light blue, greenish, gray, or brown.

Battery corrosion manifests in various forms, including white powdery substances and greenish or bluish deposits. Recognizing these signs early on allows for timely intervention to prevent further damage and ensure optimal battery performance. Regular inspection and cleaning of terminals are essential for maintaining a healthy electrical system.

Does Battery Corrosion Mean a Bad Battery?

Corrosion on the battery terminals does not necessarily indicate a bad battery.

Many wonder if battery corrosion is synonymous with a bad battery. Understanding the correlation between corrosion and battery health is essential for proper maintenance and troubleshooting.

- Sign of Malfunction: While corrosion doesn’t always indicate a failing battery, it can be a symptom of operational issues or improper maintenance, potentially affecting battery performance.

- User Error: Sometimes, corrosion results from user errors or charging irregularities rather than intrinsic battery problems. Proper care and maintenance can mitigate these issues.

- Normal Condition: In deep cycling applications like RVs or boats, battery corrosion is common due to gas release during discharges and recharges. However, opting for lithium batteries can offer a safer and more efficient alternative.

Battery corrosion isn’t necessarily a definitive sign of a bad battery but can indicate underlying issues that require attention. Proper maintenance and considering alternative battery options like lithium can help mitigate corrosion-related problems and ensure reliable performance.

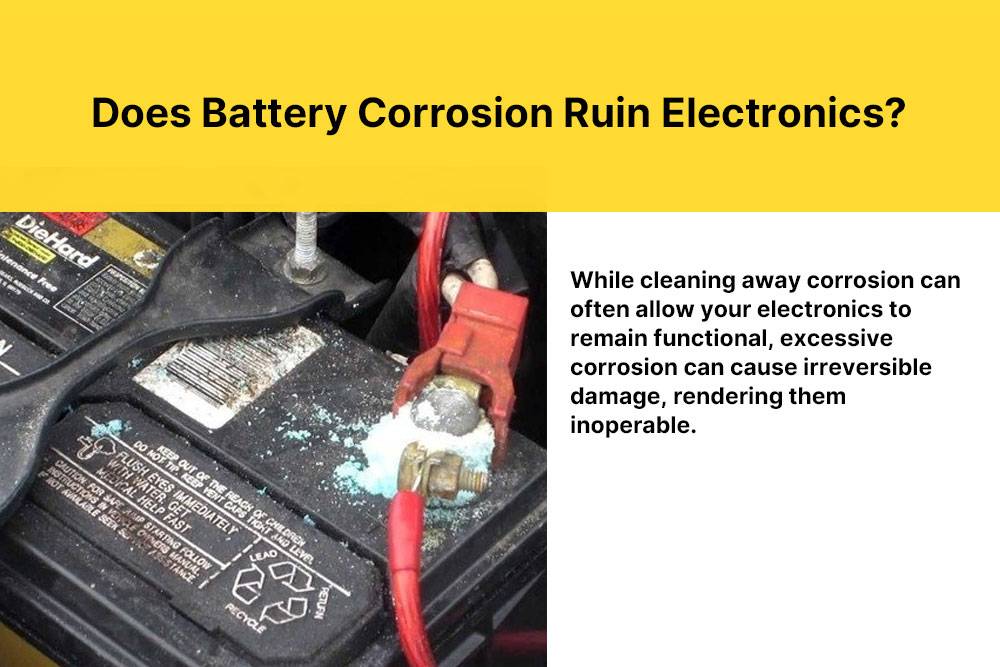

Does Battery Corrosion Ruin Electronics?

Understanding the potential impact of battery corrosion on electronic devices is vital for safeguarding valuable equipment and ensuring uninterrupted operation. Let’s explore how battery corrosion can affect electronics and strategies to prevent damage.

- Compromised Connections: Battery corrosion can compromise electrical connections, leading to erratic behavior or failure of electronic devices connected to the battery.

- Risk of Damage: Major leaks or extensive corrosion can allow corrosive substances and gases to infiltrate electronic components, causing irreversible damage and rendering the devices inoperable.

- Preventive Measures: Proper ventilation and placement of batteries, along with regular maintenance, can help mitigate the risk of battery corrosion damaging sensitive electronics. Consider alternative battery options like lithium to minimize the risk further.

While battery corrosion may not directly ruin electronics, it poses a significant risk by compromising connections and allowing corrosive substances to damage sensitive components. Taking preventive measures and choosing appropriate battery types are crucial steps in protecting electronic devices from corrosion-related damage.

How Do You Fix a Corroded Battery Terminal?

Fixing corroded battery terminals is essential for maintaining optimal battery performance and preventing electrical issues. Let’s explore effective methods to remedy battery corrosion and ensure reliable operation.

- Cleaning with Baking Soda Solution: Disconnect the battery cables, clean the terminals with a baking soda and water solution or a commercial cleaner, and apply petroleum jelly or terminal protectant to prevent future corrosion.

- DIY Corrosion Removal: Alternatively, create a homemade solution using baking soda and water. After disconnecting the battery, cover the corroded terminals with the solution, rinse with water, and reconnect securely.

- Consider Terminal Replacement: In severe cases of corrosion damage, replacing the terminals may be necessary. However, DIY cleaning methods can often resolve mild corrosion issues effectively.

Addressing corroded battery terminals promptly with appropriate cleaning methods and protective measures is crucial for extending battery lifespan and ensuring reliable performance. Whether using commercial products or DIY solutions, regular maintenance can prevent corrosion-related issues and preserve battery health.

Avoid Battery Terminal Corrosion by Switching to Lithium

Switching to lithium-ion batteries offers a solution to avoid battery terminal corrosion. Unlike lead-acid batteries, lithium batteries prevent corrosion by eliminating the production of corrosive gases during charging. Let’s delve into the benefits of lithium batteries for maintaining clean and corrosion-free terminals.

- No Dangerous Acid Leaks: Lithium batteries are sealed, eliminating the risk of harmful leaks associated with traditional batteries, ensuring safety and cleanliness.

- No Acidic Fumes: With lithium batteries, there’s no need to vent fumes, as they don’t produce corrosive gases during operation, contributing to a safer and cleaner environment.

- Minimal Maintenance: Unlike lead-acid batteries, lithium-ion batteries require minimal maintenance throughout their lifespan, reducing the need for regular checks and top-offs.

Switching to lithium batteries not only prevents battery corrosion but also offers additional benefits, including longevity, lightweight design, versatility in temperature conditions, and deeper discharge capabilities. Embracing this modern battery technology provides a reliable and efficient power source for various applications while minimizing maintenance efforts and ensuring long-term durability.

Say Goodbye to Battery Corrosion

Say goodbye to battery corrosion by taking proactive steps to prevent it. Regular cleaning and maintenance, coupled with exploring alternative battery technologies like lithium-ion, can significantly reduce the risk of corrosion and ensure consistent performance from your batteries and electronic devices.

Understanding the causes of battery terminal corrosion empowers you to tackle the issue effectively. By implementing preventive measures and staying informed, you can bid farewell to worries about battery corrosion. Moreover, embracing advanced lithium batteries offers a long-term solution, providing reliable power without the hassle of corrosion maintenance.