- Forklift Lithium Battery

- Golf Cart Lithium Battery

- Rack-mounted Lithium Battery

51.2V 100Ah Rackmount LiFePO4 Battery

8000 times (80% DOD 0.5C)

Optional SNMP for TELECOM - Car Starter Battery

- 12V LiFePO4 Battery

12V 150Ah Lithium RV Battery

Bluetooth App | Self-heating

LiFePO4 | Group 31

UL 1642 | IEC 62619 - 24V LiFePO4 Battery

- 36V LiFePO4 Battery

- 48V LiFePO4 Battery

- 60V LiFePO4 Battery

60V 100Ah Lithium Battery (AGV, AMR, LGV)

Peak Discharge Current 400A

500 x 298 x 349 mm - 72V~96V LiFePO4 Battery

72V 100Ah Lithium Golf Cart Battery

Peak Discharge Current 315A (10S)

740 × 320 × 246 mm - Wall-mounted Lithium Battery

51.2V 100Ah 5kWh

Wall-mounted Battery532 x 425 x 170 mm / LiFePO4

>8000 Cycles (80% DOD 0.5C)

RS485 / CAN-bus

for Solar Home ESS - Home-ESS All-in-One

51.2V 32kWh

All-in-On HESS SystemPowerAll

51.2V / LiFePO4

>8000 Cycles (80% DOD 0.5C)

RS485 / CAN-bus / WiFi

All-in-One for Home ESS

How to Calculate Battery Running Time Based on Net Capacity and Load

Battery running time estimates how long a battery powers a device before depletion, calculated from net capacity (amp-hours) and load power (watts). It hinges on the battery’s voltage, capacity, load consumption, efficiency, and allowable depth of discharge. Accurate runtime planning supports effective energy management. Redway Power’s expertise ensures batteries deliver reliable runtime predictions through quality and advanced management systems.

What Is Battery Running Time and Why Is It Important?

Battery running time indicates the duration a battery can sustain a load until depletion, pivotal for sizing systems in off-grid solar, electric vehicles, and backup power. Knowing runtime helps prevent unexpected power loss, optimizes battery usage, and extends system life by guiding users on capacity and load management.

How Do You Calculate Battery Running Time Based on Net Capacity and Load?

Running time can be calculated by dividing the net battery capacity (in watt-hours or amp-hours adjusted for usable depth) by the power load (in watts) applied. This gives a theoretical duration, adjusted further for system efficiency and battery chemistry factors to estimate real-world runtime.

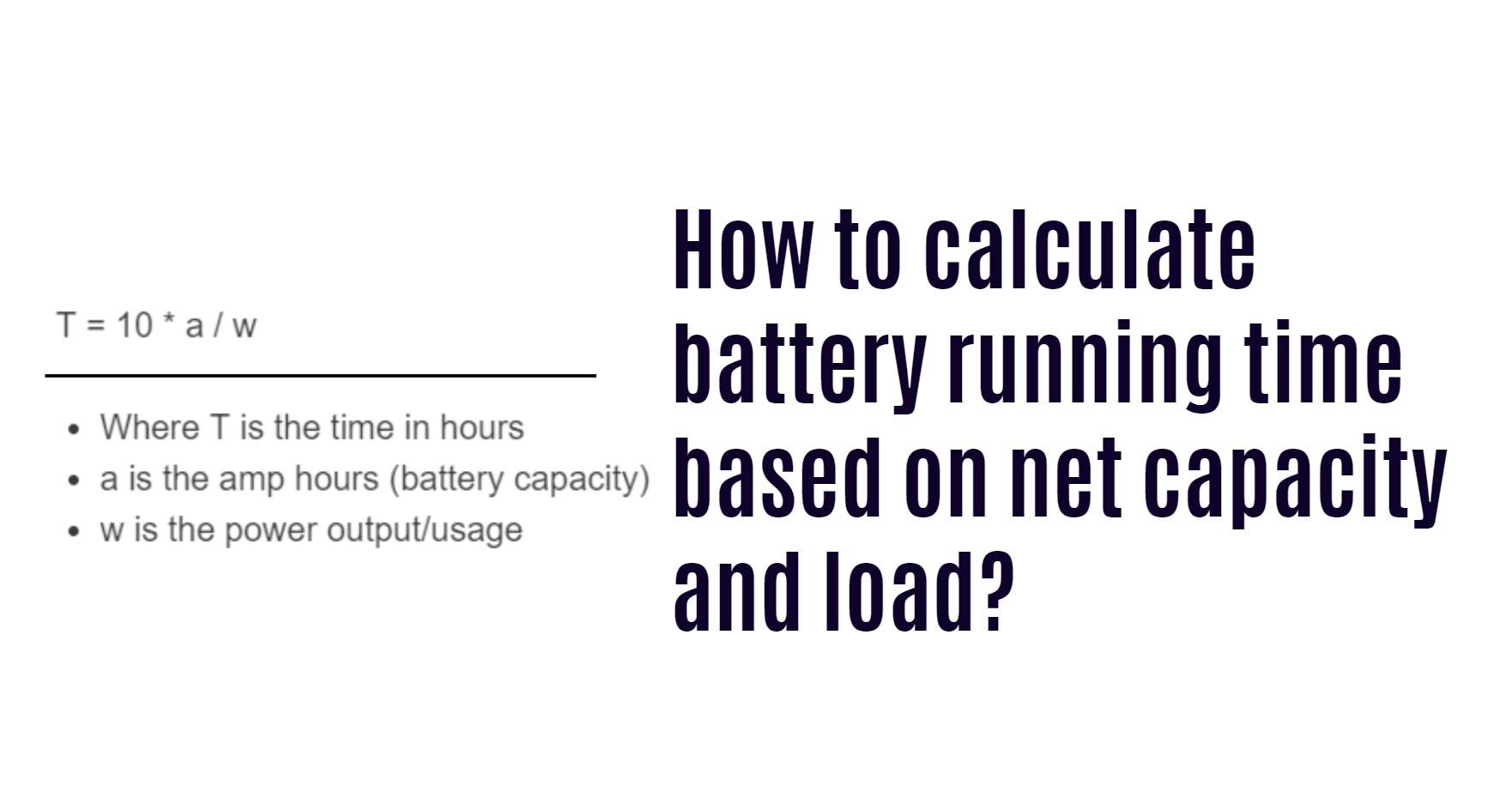

What Is the Standard Formula for Calculating Battery Runtime?

The core formula is:

Runtime (hours)=Battery Capacity (Ah)×Battery Voltage (V)×EfficiencyLoad Power (W)

Alternatively, if capacity is in watt-hours:

Runtime (hours)=Watt-hours (Wh)×EfficiencyLoad Power (W)

How Do Battery Voltage and Amp-Hour Capacity Influence Runtime?

Voltage and amp-hour ratings define total energy availability with energy measured in watt-hours (Wh = V × Ah). Higher capacity or voltage translates into more stored energy, directly extending runtime at a given load. Batteries with higher voltage or Ah sustain power longer under constant load conditions.

How Does Load Power Consumption Affect Battery Running Time?

Running time inversely depends on load power; higher wattage devices draw energy faster, decreasing battery runtime. Steady, constant loads simplify calculation, while fluctuating or surge loads require average or peak power estimates for accurate predictions.

What Role Do Efficiency and Depth of Discharge Play in Runtime Calculation?

Efficiency accounts for energy lost in conversion, internal resistance, and device performance, typically reducing usable capacity by 5-15%. Depth of Discharge (DoD) limits how much capacity can safely be used without harm; for example, lead-acid batteries should not exceed 50% DoD for longevity, while lithium batteries tolerate 80-90% DoD.

How Does Peukert’s Law Impact Runtime Estimates for Different Battery Types?

Peukert’s Law states that battery capacity decreases as discharge rate increases; at high loads, runtime is less than simple calculations suggest. Lead-acid batteries are more affected, with Peukert exponent around 1.1–1.3, whereas lithium batteries have near-linear discharge with extrapolation errors minimized.

What Practical Factors Can Affect Battery Running Time in Real Use?

Temperature, battery age, partial loads, and battery management system losses can shorten actual runtime. High or low temperatures reduce capacity, aged batteries lose efficiency, and transient loads vary consumption. Accurate runtime reflects these dynamic influences beyond theoretical formulas.

How Do Battery Chemistry Differences Affect Calculations of Runtime?

Lithium batteries maintain higher voltage during discharge and allow deeper DoD, offering longer practical runtime than lead-acid under similar capacity. Lead-acid voltage drops more steeply under load and charge cycles reduce capacity faster. Therefore, formulas must adjust for chemistry-specific efficiency and voltage profiles.

How Can Battery Management Systems (BMS) Enhance Runtime Prediction Accuracy?

BMS monitors voltage, current, temperature, and state of charge across cells, dynamically adjusting estimates and protecting against damaging conditions. Advanced BMS logs provide real-time data improving runtime forecasting and alert users to capacity reductions, maximizing dependable power delivery.

How Does Redway Power Ensure Runtime Reliability Through High-Quality Battery Manufacturing?

Redway Power incorporates ISO 9001:2015-certified manufacturing with advanced MES systems ensuring consistent battery quality and precise capacity ratings. Their batteries feature sophisticated BMS integration, enhancing efficiency, safety, and accurate runtime management, making them ideal for precision-dependent applications like telecom, solar, and electric vehicles.

Battery Runtime Calculation Chart

| Parameter | Description | Units | Typical Values |

|---|---|---|---|

| Battery Capacity (Ah) | Total charge battery stores | Amp-hours | 50 – 200 Ah |

| Battery Voltage (V) | Nominal battery voltage | Volts | 12V, 24V, 48V, etc. |

| Load Power (W) | Power consumed by the device | Watts | Varies widely |

| Efficiency (%) | System and battery efficiency factor | Percentage | 85% – 95% |

| Depth of Discharge (DoD) | Percentage of battery capacity safely usable | Percentage | 50% (lead-acid), 80% (Li-ion) |

| Runtime (hours) | Estimated operating time under load | Hours | Calculated value |

Redway Power Expert Views

“At Redway Power, we recognize that precise calculation of battery runtime fundamentally depends on quality battery construction and intelligent management. Our commitment to rigorous quality assurance and advanced Battery Management Systems allows clients to achieve dependable run time estimations, optimizing system performance and reliability across diverse demanding applications,” says a technical expert from Redway Power.

Conclusion

Calculating battery running time based on net capacity and load entails understanding the interaction of battery voltage, amp-hour capacity, load power, efficiency, and depth of discharge. Peukert’s law and real-world factors further affect runtime, necessitating sophisticated management and quality batteries for accuracy. Redway Power’s manufacturing excellence ensures consistent capacity delivery and runtime reliability, empowering users to manage their energy resources confidently.

Frequently Asked Questions

Q: How do I calculate runtime if my battery shows capacity in watt-hours?

A: Divide watt-hours by load wattage, adjusting for efficiency: Runtime (h) ≈ (Wh × Efficiency) / W.

Q: Why does running time sometimes differ from theoretical calculation?

A: Factors like battery age, temperature, Peukert’s effect, and load variations affect actual runtime.

Q: What is a safe Depth of Discharge to maximize battery life?

A: Generally 50% for lead-acid, 80-90% for lithium batteries.

Q: How can I measure load power if unknown?

A: Use wattmeters, clamp meters, or refer to device specifications.

Q: Does Redway Power provide support for runtime estimation?

A: Yes, Redway Power offers technical assistance to optimize battery sizing and runtime for customer applications.