Blog

Electric Forklifts vs. Propane: Which Is Better for Your Operations?

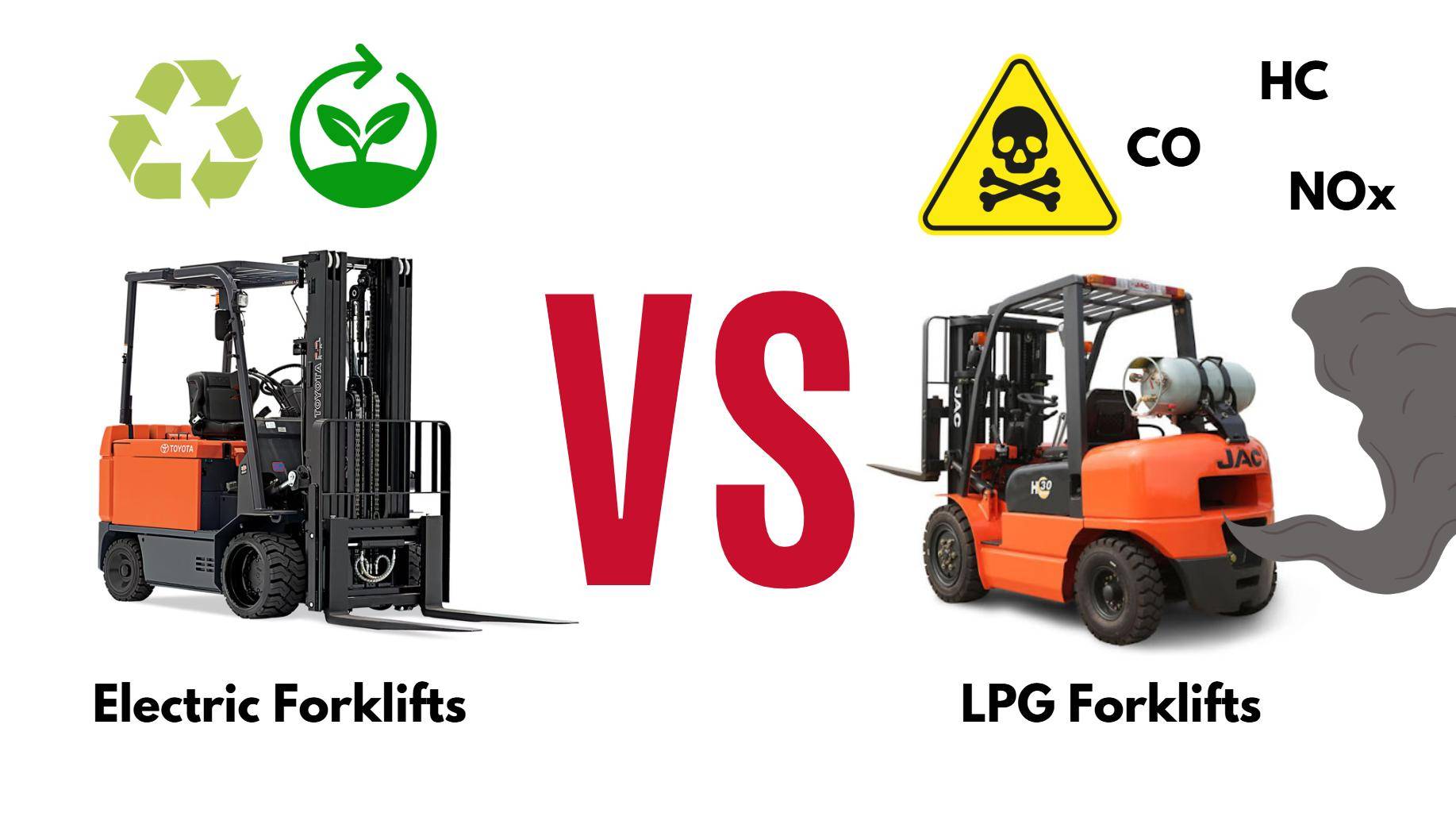

Choosing between electric and propane forklifts represents a critical decision for businesses balancing operational efficiency, cost management, and sustainability goals. While electric models dominate indoor environments with zero emissions and quiet operation, propane forklifts remain indispensable for heavy outdoor lifting and cold storage applications. This comprehensive guide breaks down costs, environmental impacts, and practical considerations to help operations managers and business owners make informed decisions.

LiFePO4 Forklift Batteries OEM Manufacturer

Electric forklifts and propane forklifts each offer distinct advantages and challenges, making the best choice dependent on your specific operational needs. Electric forklifts excel in indoor environments with zero emissions, lower maintenance, and quieter operation, while propane forklifts provide longer run times, faster refueling, and greater power for heavy-duty or outdoor use. Redway Power’s lithium battery technology enhances electric forklifts’ efficiency and reliability, making them increasingly competitive.

What Are the Key Differences Between Electric and Propane Forklifts?

Electric forklifts run on rechargeable batteries, typically lithium-ion or lead-acid, producing zero emissions and low noise, ideal for indoor use. Propane forklifts use liquefied petroleum gas, offering consistent power and quick refueling, suited for mixed indoor/outdoor environments and heavy lifting.

How Do Electric Forklifts Benefit Indoor Operations?

Electric forklifts produce no exhaust fumes, making them safe for enclosed spaces with strict air quality standards. They operate quietly, reducing noise pollution, and require less routine maintenance due to fewer moving parts, lowering operating costs over time.

What Advantages Do Propane Forklifts Offer for Heavy-Duty and Outdoor Use?

Propane forklifts deliver higher torque and consistent power throughout shifts, ideal for demanding lifting tasks and rough terrain. They can be refueled in minutes, minimizing downtime, and perform reliably in various weather conditions, including cold and wet environments.

How Do Operating Costs Compare Between Electric and Propane Forklifts?

While propane forklifts have lower upfront costs, electric forklifts save money on fuel and maintenance over their lifespan. Electric models avoid expenses related to engine tune-ups, oil changes, and fuel storage, and Redway Power’s lithium batteries reduce charging time and extend battery life, further cutting costs.

What Are the Environmental Impacts of Each Forklift Type?

Electric forklifts have zero tailpipe emissions, supporting sustainability goals. Propane forklifts emit low levels of carbon monoxide and hydrocarbons but require proper ventilation indoors. Lifecycle emissions for electric forklifts include battery manufacturing impacts, which are mitigated by advanced recycling programs.

How Does Refueling and Charging Affect Forklift Productivity?

Propane forklifts can resume operation quickly by swapping tanks in minutes, supporting continuous multi-shift work. Electric forklifts require longer charging times, though fast-charging lithium-ion batteries from Redway Power can reduce downtime significantly.

Which Forklift Type Is Better for Your Specific Application?

Choose electric forklifts for indoor warehouses, cold storage, or facilities with emission restrictions. Opt for propane forklifts when heavy lifting, outdoor use, or continuous operation without long charging breaks is required.

Chart: Electric vs. Propane Forklift Comparison

| Feature | Electric Forklift | Propane Forklift |

|---|---|---|

| Emissions | Zero tailpipe emissions | Low emissions, requires ventilation |

| Noise Level | Quiet operation | Noisier combustion engine |

| Upfront Cost | Higher due to battery and charger | Lower initial purchase price |

| Operating Cost | Lower fuel and maintenance costs | Higher fuel and engine upkeep |

| Refueling/Charging | Longer charging, fast with Li-ion | Quick tank swaps |

| Power & Torque | Instant torque, may drop as battery drains | Consistent power throughout shift |

| Suitable Environments | Indoor, clean rooms, warehouses | Indoor/outdoor, rough terrain |

Electric vs. Propane Forklifts: Key Operational Differences

Electric forklifts shine in indoor settings, eliminating harmful emissions and reducing noise pollution to 65 dB—quieter than a standard office conversation. Their instant torque delivery ensures precise load handling in tight warehouse aisles. Propane counterparts, however, deliver 15-20% greater lifting capacity (up to 15,000 lbs vs. electric’s 12,000 lbs maximum) and operate reliably in temperatures as low as -22°F, making them ideal for lumber yards or frozen food warehouses. A Midwest auto parts distributor reported a 40% productivity boost after deploying propane forklifts in their unheated loading docks during winter months.

Cost Analysis: Upfront Investment vs. Long-Term Savings

| Cost Factor | Electric Forklift | Propane Forklift |

|---|---|---|

| Initial Purchase | $28,000–$45,000 | $18,000–$32,000 |

| 5-Year Fuel Expenses | $4,200 (0.25 kWh rate) | $16,800 ($3/gal) |

| Annual Maintenance | $1,800 (battery care, motor checks) | $3,200 (engine tune-ups, exhaust repairs) |

While electric models require a 20-40% higher initial investment, they save $12,600 in fuel and $7,000 in maintenance costs over five years compared to propane. Operations exceeding 2,000 annual hours often break even on electric’s premium within 2-3 years. Third-party leasing options—like Toyota’s 60-month battery-as-a-service program—can reduce upfront costs by 30% while including free battery replacements.

Environmental Impact: Emissions and Energy Sources

| Environmental Metric | Electric | Propane |

|---|---|---|

| CO2 Emissions (8-hour shift) | 13.6 lbs* | 203 lbs |

| Energy Source Flexibility | Solar/Wind/Grid | Fossil Fuel Only |

| Particulate Matter | 0g | 0.02g/gal |

*Based on U.S. grid average. Facilities using renewable energy can reduce electric forklift emissions by 92%. Modern propane engines meet EPA Tier 4 standards, cutting nitrogen oxide emissions by 90% versus older models. However, electric fleets remain the only viable option for companies pursuing LEED certification, as they contribute to 7 of the 9 energy efficiency credits.

Technological Advancements Reshaping the Industry

Lithium-ion batteries now enable 80% charges in 60 minutes, supporting multi-shift operations without battery swaps—a game-changer for e-commerce fulfillment centers. Crown’s QuickCharge® systems, for example, allow overnight charging for three consecutive shifts. Propane innovations include fuel-injection engines that improve efficiency by 20%, though they still can’t match electric’s $0.25/hour operating cost. Telematics integration in both systems enables real-time fuel monitoring, with companies like Raymond linking usage data to warehouse management systems to optimize routes.

Frequently Asked Questions

- Can electric forklifts handle heavy loads in cold storage?

- Yes—new lithium-ion models maintain 95% capacity at -4°F. Walgreens recently deployed 20 electric forklifts in their -20°F pharmaceutical warehouses, reducing energy costs by $18,000 annually versus propane.

- How does battery disposal work for electric models?

- Major manufacturers like CATL and BYD offer closed-loop recycling recovering 98% of lithium. The process extracts cobalt, nickel, and lithium for reuse, creating a 70% smaller environmental footprint than mining new materials.

- Are propane forklifts viable for urban warehouses?

- Increasingly less so—cities like Los Angeles now mandate zero-emission equipment in ports and logistics hubs. Propane remains practical only in rural areas without strict air quality regulations.

Are electric or propane forklifts better?

The choice depends on your needs: electric forklifts offer lower long-term costs, zero emissions, and quieter operation, best for indoor use; propane forklifts provide longer runtime, consistent power, and quick refueling, making them better for multi-shift or outdoor environments where power and speed are essential.

What is an advantage of using electric-powered forklifts?

Electric forklifts produce zero tailpipe emissions, operate quietly, have lower maintenance costs, and offer improved safety with better stability and visibility, making them ideal for indoor environments and sensitive applications.

What are the primary differences between propane and electric forklifts in terms of operation and safety considerations?

Propane forklifts run longer per refuel and maintain full power but emit exhaust and need fuel storage. Electric forklifts have quieter, emission-free operation with lower maintenance but need long battery charging and watering, affecting runtime and scheduling.

What are two advantages of electric forklifts over gas-powered models when used in an enclosed area?

Electric forklifts generate no harmful emissions and operate much quieter, improving indoor air quality and reducing noise pollution, which enhances worker safety and comfort in enclosed warehouse spaces.

How To Use A Propane Vs Electric Forklift Calculator?

Input your forklift usage hours, energy costs, and maintenance expenses into the calculator to compare total operating costs and efficiency differences between propane and electric forklifts, helping determine the most cost-effective option for your operation.

Implementation Strategies for Maximum ROI

Conduct an energy audit to determine:

- Daily operating hours and shift patterns

- Average load weights and travel distances

- Indoor/outdoor usage ratios

For mixed fleets, deploy electric for 80% of indoor tasks and propane for heavy outdoor lifts. Nebraska-based retailer Orscheln saved $58,000 annually by transitioning 75% of its fleet to electric, keeping propane units only for loading delivery trucks.

The Bottom Line: Electric forklifts deliver superior lifetime value for single-shift indoor operations, while propane retains an edge in extreme conditions. With battery tech advancing rapidly and sustainability mandates multiplying, electric adoption is projected to grow 14% annually through 2030—making now the ideal time to evaluate your transition roadmap.