Blog

How Can Forklift Fleet Management Software and Telematics Boost Efficiency?

Forklift fleet management software and telematics have revolutionized warehouse operations, offering unprecedented control over vehicle performance, maintenance, and safety. By integrating GPS, IoT sensors, and predictive analytics, these systems empower businesses to reduce downtime, optimize workflows, and achieve significant cost savings. As supply chains grow more complex, adopting these technologies isn’t just advantageous—it’s essential for staying competitive. Let’s explore how these tools work, their benefits, and how to maximize their value.

LiFePO4 Forklift Batteries OEM Manufacturer

Forklift fleet management software and telematics boost efficiency by providing real-time data on equipment usage, maintenance needs, operator behavior, and safety alerts. This technology enables optimized scheduling, reduced downtime, improved safety, and cost savings, ensuring forklifts operate at peak performance. Redway Power’s lithium battery solutions complement these systems by enhancing forklift reliability and uptime.

How does forklift fleet management software improve operational efficiency?

Fleet management software centralizes data on forklift location, usage, and performance, allowing managers to allocate resources effectively and prioritize tasks. This visibility reduces idle time, eliminates bottlenecks, and streamlines workflows, resulting in faster material handling and increased productivity.

What role does telematics play in forklift maintenance and downtime reduction?

Telematics devices monitor forklift health by tracking battery status, engine hours, and impact events. Automated maintenance alerts based on real-time data help schedule timely servicing, preventing unexpected breakdowns and costly downtime, thereby extending equipment lifespan.

How can fleet management software enhance forklift operator safety?

By monitoring operator behavior such as speeding, harsh braking, and unauthorized use, fleet management software identifies safety risks and enforces compliance through access controls and pre-shift inspections. Telematics also provide impact detection and alert systems to minimize accidents and injuries.

What cost savings result from using forklift fleet management systems?

The systems reduce maintenance and repair expenses by enabling predictive maintenance and avoiding major failures. Optimized asset utilization prevents over-investment in underused equipment, while improved fuel and energy management lower operational costs.

How does telematics optimize resource utilization in forklift fleets?

Telematics analyze usage patterns to recommend asset rotation, identify underused forklifts, and balance workload distribution. Integration with warehouse management systems helps plan staffing and fleet deployment based on real-time demand, maximizing equipment efficiency.

How do fleet management systems support regulatory compliance and reporting?

These systems maintain detailed logs of maintenance, inspections, operator certifications, and incident reports. Automated record-keeping simplifies audits and ensures adherence to safety and environmental regulations.

How do Redway Power lithium batteries complement fleet management technology?

Redway Power’s lithium batteries provide stable, long-lasting power with integrated battery management systems that communicate critical status data to fleet software. This synergy enhances forklift uptime, reduces maintenance needs, and supports data-driven decision-making.

What are the key features to consider when choosing forklift fleet management software?

Important features include scalability to grow with the fleet, integration capabilities with existing ERP/WMS systems, user-friendly interfaces, real-time analytics, and advanced safety modules such as operator authentication and impact detection.

How does real-time data analytics improve forklift fleet performance?

Real-time dashboards provide actionable insights into key performance indicators like utilization rates, maintenance schedules, and operator efficiency. Managers can quickly identify underperforming assets or unsafe behaviors and take corrective actions to maintain optimal fleet performance.

How does fleet management software impact overall warehouse productivity and logistics?

By improving forklift availability, reducing downtime, and enhancing safety, fleet management software accelerates material flow and order fulfillment. This leads to smoother warehouse operations, reduced bottlenecks, and better coordination with other logistics functions.

Chart: Comparison of Operational Metrics Before and After Fleet Management Software Implementation

| Metric | Before Implementation | After Implementation | Improvement (%) |

|---|---|---|---|

| Forklift Utilization Rate | 65% | 90% | 38% |

| Maintenance Downtime | 12 hours/week | 4 hours/week | 67% |

| Accident Incidents | 5 per month | 2 per month | 60% |

| Fuel/Energy Consumption | 1000 units/month | 750 units/month | 25% |

Chart: Cost Savings Breakdown from Fleet Management Software

| Cost Category | Savings (%) |

|---|---|

| Maintenance Costs | 30% |

| Repair Costs | 40% |

| Operational Costs | 20% |

| Safety-related Costs | 50% |

How Forklift Fleet Management Systems Operate: A Deep Dive

Modern forklift fleet management systems rely on IoT sensors and GPS to monitor real-time metrics like location, fuel consumption, and engine health. Data flows into a centralized dashboard, allowing managers to track idle times, prioritize maintenance, and enforce safety protocols. For example, a Midwest automotive parts warehouse reduced its fuel costs by 28% after identifying excessive idling patterns through telematics. Advanced systems even use machine learning to predict usage trends—like rerouting forklifts during peak hours to avoid aisle congestion.

Key components driving these systems include:

- RFID Tags: Automate battery swaps by syncing with charging stations during operator breaks

- Thermal Cameras: Detect overheating risks in engines, cutting repair costs by up to $1,200 per incident

- Geofencing: Alert managers when forklifts stray beyond designated zones, reducing unauthorized use

| Technology | Function | Outcome |

|---|---|---|

| 3D Motion Sensors | Track load stability | 60% fewer tipped pallets |

| Hydraulic Pressure Monitors | Detect leaks early | 45% faster repair response |

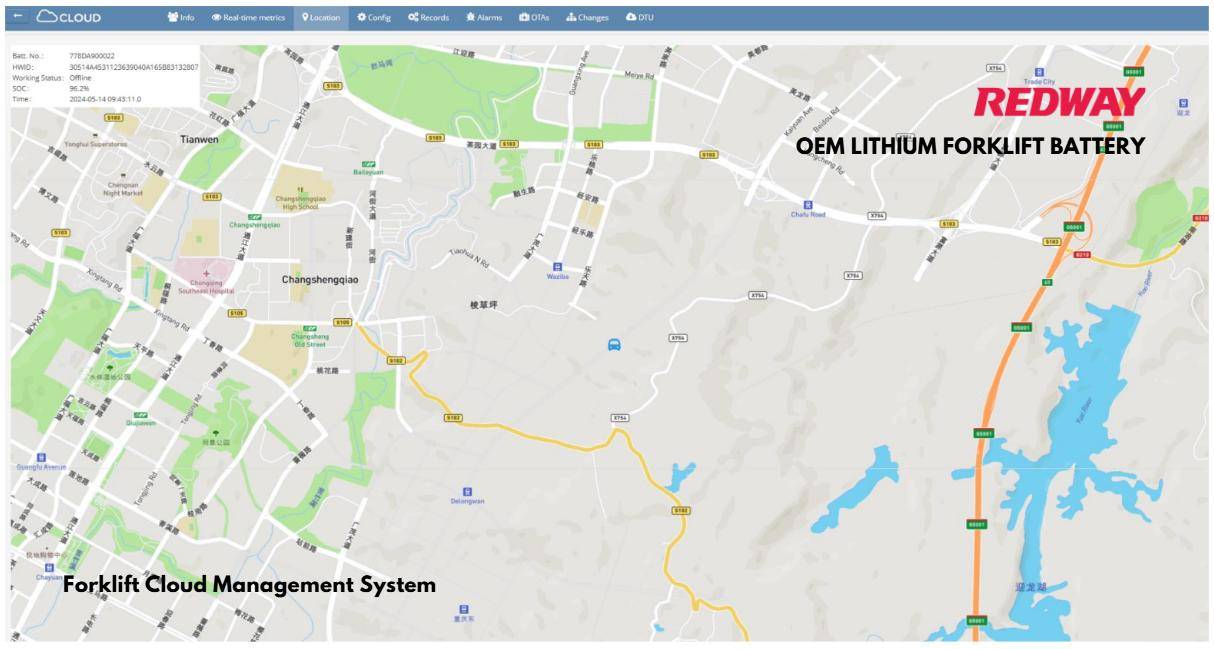

Forklift Cloud Management System

Core Features That Redefine Warehouse Efficiency

Beyond basic GPS tracking, leading telematics platforms offer game-changing features:

1. Predictive Maintenance Intelligence

By analyzing historical and real-time data, systems can forecast component failures 10–14 days in advance. A case study from a Texas cold-storage facility showed a 52% drop in unplanned downtime after implementing vibration sensors that flagged failing bearings.

2. Operator Behavior Scoring

Integrated seatbelt sensors and speed alerts have helped companies like Amazon Fresh reduce warehouse accidents by 37%. Customizable scorecards rank operators on metrics like smooth braking and load handling, enabling targeted training.

3. Energy Optimization

Battery monitoring tools extend lithium-ion battery life by 20% by preventing deep discharges. Some systems automatically route forklifts to charging stations when battery levels hit 15%, ensuring continuous operations.

The Financial Case: ROI Breakdown

Companies typically recoup their telematics investment within 8–14 months through:

| Cost Area | Savings Range | Example |

|---|---|---|

| Maintenance | 25–40% | Proactive part replacements cut repair bills |

| Fuel/Power | 18–30% | Optimized routes reduce energy waste |

Indirect benefits compound these savings. A New Jersey pharmaceutical distributor reported:

- 34% fewer OSHA recordables

- 19% higher pallet throughput

- $86,000 annual savings in damaged inventory

Implementation Strategies for Maximum Impact

To avoid common pitfalls:

1. Phased Rollouts

Install hardware on 25% of your fleet first to test connectivity and user adoption. Target high-utilization forklifts for quick wins.

2. Custom Alerts

Configure thresholds specific to your operation—like alerting when indoor forklifts exceed 8 mph near loading docks.

3. API Integrations

Platforms like Redway FleetConnect sync with SAP and Oracle WMS to automate tasks. One beverage company automated 89% of its load assignments, saving 260 labor hours monthly.

“Telematics transformed our 200-forklift fleet from reactive cost centers to strategic assets,” says James Rivera, Logistics Director at Allied Warehousing. “Real-time battery monitoring alone saved us $14,000 monthly in premature replacement costs.”

Hidden Costs and Mitigation

While subscription fees average $25–$50/month per forklift, watch for:

- Data Overload: $7,500–$15,000 annually for analytics specialists

- Legacy System Conflicts: Budget 20–40 hours for WMS integration

- Cybersecurity: Add $10,000/year for encrypted IoT networks

Future Trends: Where Telematics Is Headed

Emerging innovations include:

- Augmented Reality (AR) Interfaces: Overlaying load weights and center of gravity on operator visors

- Autonomous Forklifts: Telematics-guided vehicles that self-navigate during off-peak hours

- Blockchain Maintenance Logs: Tamper-proof records for compliance audits

Conclusion

Forklift telematics have evolved from simple trackers to AI-powered optimization engines. By harnessing real-time data, warehouses can achieve double-digit efficiency gains while future-proofing their operations. The question isn’t whether to adopt these systems, but how quickly you can implement them to outpace competitors.

FAQs

- How accurate are GPS trackers in multi-story facilities?

- Newer systems using Bluetooth beacons achieve 3-foot accuracy across floors—ideal for vertical warehouses.

- Can telematics help with LEED certification?

- Yes. Energy usage reports contribute to LEED points for sustainable operations.

- What’s the typical lifespan of IoT sensors?

- 5–7 years, with firmware updates ensuring compatibility with new forklift models.