Ternary lithium batteries, recognized for their global usage and safety measures, feature a crucial protection plate. This plate serves to manage elements like overcharging and overheating, ensuring their secure application. Widely embraced for small high-power batteries worldwide, these batteries find a prominent place in high-end Tesla cars. While continuous safety enhancements have been implemented, this introduction aims to address common curiosities about ternary lithium batteries, reassuring readers that adherence to instructions guarantees a safe and reliable experience.

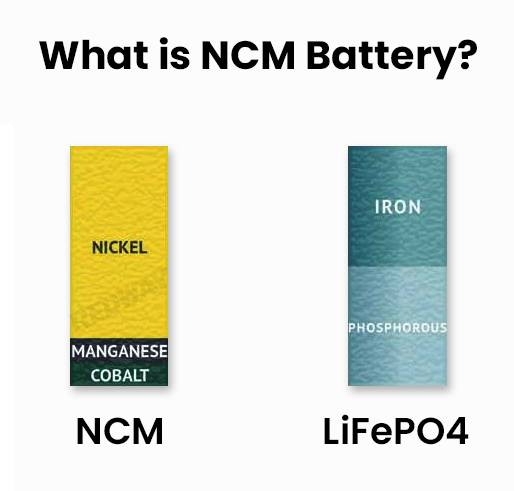

What is NCM Battery?

NCM battery, also known as the “Ternary lithium battery,” incorporates nickel, cobalt, and manganese in its cathode composition. Increased nickel levels pose challenges by making Li+ removal more difficult, leading to reduced capacity and cycling. Higher nickel content results in an unstable Ni3+ proportion, intensifying reactions with moisture and CO2, thereby impacting overall performance. The term “ternary” originates from the three cathode metals: nickel (Ni), cobalt (Co), and manganese (Mn). Varied ratios, such as 1:1:1, 5:2:3, and 8:1:1, create distinct compounds, forming the basis for the fixed compound materials in Ternary lithium batteries.

Why we use Ni, Co and Mn in ternary lithium battery ?

Nickel (Ni) exhibits low reactivity at room temperature, hindering oxidation in air. The presence of Ni ions contributes to a higher volumetric energy density.

Cobalt (Co) remains stable in humid air and is unreactive with water at room temperature. Despite its relatively high cost, the laminar structure of the material enhances stability, reduces impedance values, and improves conductivity and cycling performance through the presence of Co ions.

Manganese (Mn) is inherently stable, resistant to oxidation or reduction. The inclusion of Mn ions enhances material safety and stability.

Safety Concerns with Ternary Lithium Batteries

Ternary lithium batteries, while widely used, pose certain safety concerns. Understanding and addressing these issues is essential for responsible usage.

-

Overheating and Fires:

- Ternary lithium batteries are prone to overheating and fires, particularly when damaged or mishandled.

- Proper handling practices and adherence to safety guidelines are crucial to prevent incidents of overheating and fires.

-

Comparison with LiFePO4 Batteries:

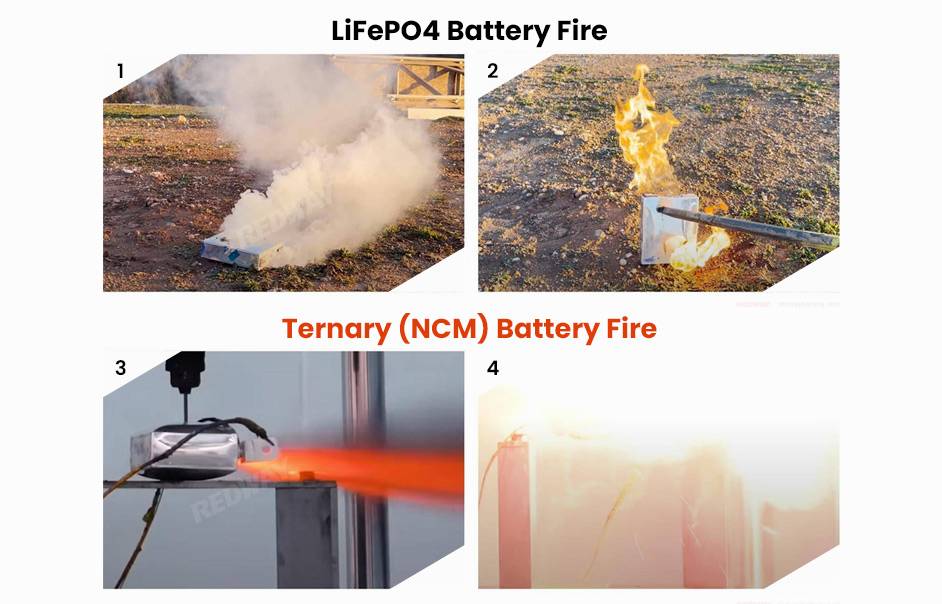

- Ternary lithium batteries have a lower thermal runaway temperature compared to lithium iron phosphate (LiFePO4) batteries.

- This makes them more susceptible to catching fire at high temperatures, emphasizing the need for cautious use.

-

Charging Guidelines:

- Charging ternary lithium batteries requires strict adherence to specific guidelines, including using a charger designed for lithium-ion batteries.

- Monitoring the charging process, avoiding overcharging, and following manufacturer specifications are essential safety measures.

Conclusion: Understanding and addressing these safety concerns ensures responsible use of ternary lithium batteries, minimizing risks and promoting safe utilization in various applications.

How to charge Ternary Lithium Battery?

Charging a ternary lithium battery, also known as a lithium-ion battery with a ternary cathode, requires careful adherence to specific guidelines. Follow these steps to ensure safe and efficient charging.

-

Choose the Right Charger:

- Select a charger designed explicitly for lithium-ion batteries and compatible with your ternary lithium battery’s voltage and capacity.

- Using the correct charger prevents damage and ensures safety during the charging process.

-

Check Battery Specifications:

- Review the manufacturer’s guidelines or datasheet for your ternary lithium battery.

- Note the recommended voltage range, charging current, and any specific instructions provided by the manufacturer.

-

Prepare the Charging Environment:

- Charge the battery in a well-ventilated area with a stable surface, away from flammable materials.

- Avoid extreme temperatures, direct sunlight, or exposure to moisture during charging.

-

Connect the Charger:

- Securely connect the charger’s positive (+) and negative (-) terminals to the corresponding battery terminals.

- Ensure a proper connection to prevent loose or intermittent contacts.

-

Set the Charging Parameters:

- Adjust the charger settings based on the battery specifications.

- Set the charging voltage and current as recommended by the manufacturer.

-

Monitor the Charging Process:

- Keep an eye on the charging process and check the battery temperature periodically if possible.

- Charger indicators or displays can show the charging status or progress.

-

Charge to Full Capacity:

- Allow the battery to charge until it reaches its full capacity.

- Avoid overcharging to prevent reduced battery life and potential safety hazards.

-

Disconnect the Charger:

- Once fully charged, disconnect the charger from the battery terminals.

- Safely unplug the charger from the power source.

Conclusion: While these steps provide general guidance, always refer to the specific instructions and guidelines provided by the ternary lithium battery manufacturer for safe and optimal charging of your particular battery model.

How to store Ternary (NCM) lithium battery?

Ensuring the proper storage of ternary lithium batteries is crucial for maintaining their performance, safety, and longevity. Follow these guidelines to store your batteries effectively.

-

Charge the Battery:

- Charge the battery to around 50-60% of its capacity before storage to prevent over-discharge and minimize stress on the battery.

-

Temperature and Humidity:

- Store batteries in a cool and dry environment, avoiding extreme temperatures that can impact performance.

- Aim for a storage temperature range of 15°C25°C (59°F77°F) and humidity levels below 50%.

-

Avoid Direct Sunlight:

- Keep batteries away from direct sunlight to prevent heat and UV radiation exposure, which can degrade performance and pose safety risks.

-

Battery Enclosure:

- Store batteries in a non-conductive and non-metallic container to prevent accidental short-circuits and physical damage.

-

Ventilation:

- Ensure proper ventilation in the storage area, especially when storing multiple batteries, to prevent the accumulation of flammable gases.

-

Separate Storage:

- If storing multiple batteries, keep them individually or use insulating material to prevent contact and potential short-circuiting.

-

Regular Check-ups:

- Periodically inspect stored batteries for damage, leakage, or swelling.

- Handle any damaged batteries with care and dispose of them following recycling guidelines.

-

Recharge:

- If batteries have been in storage for an extended period, recharge them to the appropriate voltage level before use to ensure optimal performance and safety.

Conclusion: Follow these guidelines and refer to the manufacturer’s recommendations for specific requirements related to storing ternary lithium batteries. By doing so, you can maintain the performance and safety of your batteries during storage, ensuring they are ready for use when needed.

What’s Lithium Iron Phosphate (LiFePO4) Battery?

Lithium iron phosphate batteries use lithium iron phosphate as their cathode material, making them more stable and safer than ternary lithium batteries. The P-O chemical bond of lithium iron phosphate is relatively stable, decomposing only at very high temperatures of 700°C~800°C. Even if the battery is deformed or damaged, oxygen molecules will not be released, preventing violent combustion. LiFePO4 battery can withstand high temperatures of 60°C.。

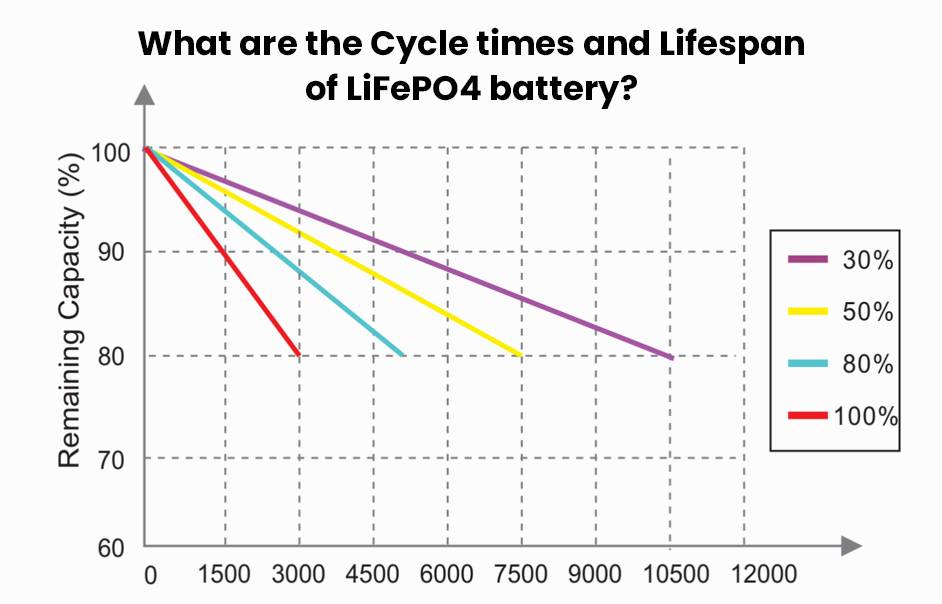

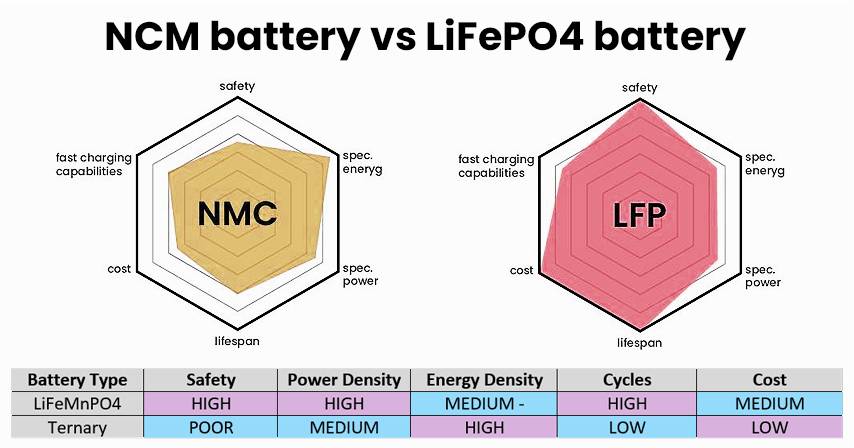

Safety Advantages of Lithium Iron Phosphate Batteries

LFP batteries offer several safety advantages over ternary lithium batteries. They are less prone to overheating and catching fire, making them a safer choice for a wide range of applications. LFP batteries have a higher thermal runaway temperature, which means they can withstand higher temperatures without catching fire. They are also more resistant to physical damage due to the steel encapsulation of the cells, making them more durable than ternary lithium batteries. Lastly, LFP batteries have a longer lifespan and are more stable, leading to fewer capacity losses with each charge/discharge cycle.

Applications for Lithium Iron Phosphate Batteries

Due to their safety and durability, LFP batteries are increasingly being used in applications that require a high level of safety, such as electric vehicles, cordless tools, and medical devices. LFP batteries are less likely to overheat or be damaged by physical contact, making them a more reliable choice in high-drain applications.

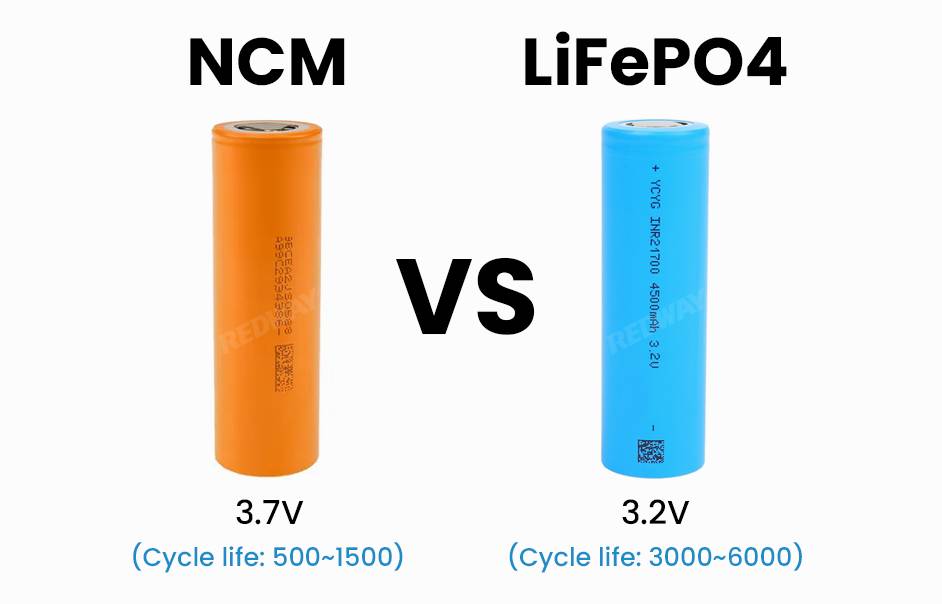

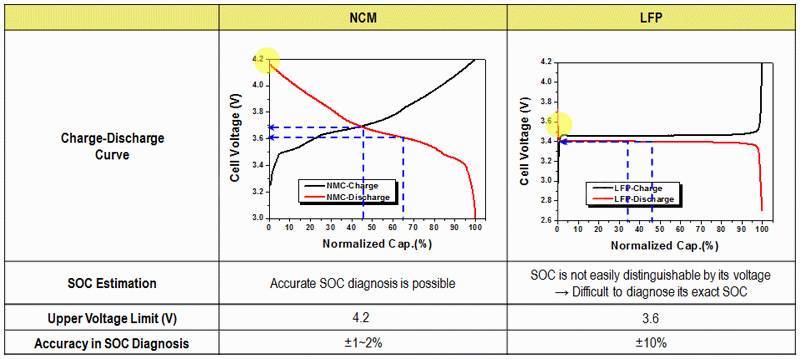

NCM battery vs LiFePO4 battery

Ternary lithium batteries (NCM) and lithium iron phosphate (LiFePO4) batteries are two different types of lithium-ion batteries, each with its own characteristics and advantages.

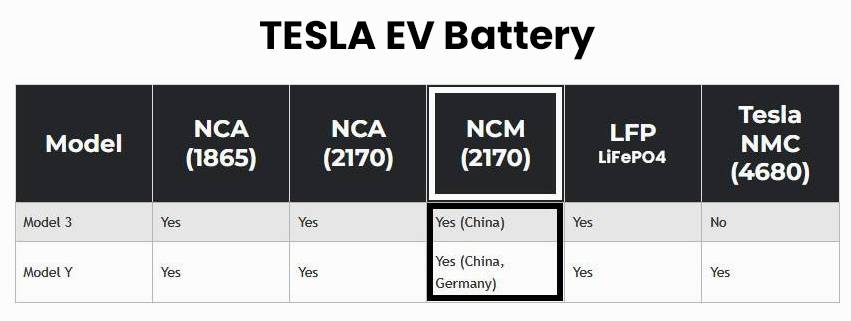

Tesla electric vehicle (EV) and NMC batteries

Tesla’s success in the electric vehicle (EV) industry is fueled by their groundbreaking use of ternary lithium batteries, specifically NMC (nickel-manganese-cobalt) batteries, in the Model series EVs. Here are three key reasons behind the prominence of these advanced batteries in Tesla’s innovation:

-

Cutting-Edge Battery Technology:

- Tesla stands out by pushing the boundaries of battery technology.

- Ternary lithium batteries, combining nickel, manganese, and cobalt, showcase innovation in the heart of Tesla’s Model series EVs.

-

High Energy Density and Stability:

- Ternary lithium batteries provide Tesla vehicles with remarkable energy density, ensuring extended range capabilities.

- The incorporation of nickel, manganese, and cobalt guarantees both high energy density and stability during operation, contributing to a reliable driving experience.

-

Enhanced Safety Measures:

- Safety is a top priority for Tesla, and ternary lithium batteries play a crucial role.

- These batteries exhibit enhanced thermal stability, reducing the risk of overheating or fires during extreme conditions, ensuring a secure driving environment.

In summary, Tesla’s reliance on ternary lithium batteries reflects their commitment to cutting-edge technology, improved performance, and elevated safety standards in the electric vehicle industry.

FAQs

How can battery performance be made transparent?

Battery performance can be made transparent by implementing real-time battery diagnostics that provide accurate insights into the battery’s health and state-of-charge. By leveraging advanced monitoring systems and technologies, such as smart sensors and data analytics, it is possible to track battery performance metrics continuously and provide users with crucial information regarding the battery’s status and anticipated lifespan. Additionally, developing user-friendly interfaces and communication tools that display battery diagnostics clearly and intuitively can help make battery performance transparent to consumers and operators. Overall, enhancing transparency in battery performance involves integrating proactive monitoring solutions that enable timely interventions and informed decision-making to optimize battery usage and prolong its lifespan.

What are the potential future battery technologies mentioned in the passage?

The passage discusses several potential future battery technologies, highlighting their specific characteristics and limitations. These technologies include solid-state Li-ion batteries, lithium-sulfur batteries, and lithium-air batteries. The solid-state Li-ion battery offers high specific energy, but it has drawbacks in terms of loading capacity and safety. Similarly, lithium-sulfur batteries present high specific energy, but they suffer from poor cycle life and loading capabilities. On the other hand, lithium-air batteries also boast high specific energy but face challenges related to loading, operational environment requirements, and a shorter operational lifespan.

What are the advantages and specifications of Lithium Titanate (Li2TiO3) batteries?

Lithium Titanate (Li2TiO3) batteries offer several advantages compared to conventional Li-ion batteries with graphite anodes. One key advantage is the zero-strain property of Li-titanate, which helps prevent issues such as lithium plating and the formation of SEI films during fast charging and charging at low temperatures. These batteries also demonstrate superior thermal stability under high temperatures when compared to other Li-ion systems.

Although Li-titanate batteries have a relatively low specific energy of 65Wh/kg, similar to that of NiCd batteries, they have the benefit of charging to 2.80V/cell and reaching the end of discharge at 1.80V/cell. This specification allows for reliable performance within these voltage ranges.

Li-titanate batteries are known for being more expensive than other types of batteries; however, they are commonly used in applications requiring high performance and durability. Some typical uses of Li-titanate batteries include electric powertrains, uninterruptible power supplies (UPS), and solar-powered street lighting systems.

How have advancements in materials and additives improved the performance of NMC batteries in recent years?

Advancements in materials and additives have significantly enhanced the performance of nickel-manganese-cobalt (NMC) batteries in recent years. By combining nickel and manganese, NMC batteries have seen notable improvements, allowing for higher charging voltages of up to 4.4V per cell, which boosts the battery’s capacity. The utilization of new electrolytes and additives has played a crucial role in achieving these advancements. This cathode combination exhibits excellent overall performance and particularly excels in specific energy metrics.

Furthermore, the ability to blend nickel, manganese, and cobalt in varying proportions has expanded the applications of NMC batteries across diverse sectors, including automotive and energy storage systems. This versatility enables the customization of NMC batteries to suit a wide range of requirements, especially those necessitating frequent cycling. Additionally, the economic feasibility of constructing NMC-blended Li-ion systems underscores the positive impact of these advancements, as they not only enhance performance but also provide a cost-effective solution for various industries.

What are the typical applications and market trends for these lithium-ion battery chemistries?

These lithium-ion battery chemistries find a variety of typical applications and exhibit certain market trends. They are known for offering high power with less capacity, while also being considered safer compared to other lithium-ion options such as Li-cobalt. A common practice is to combine these chemistries with NMC to enhance performance. They have historically been less in demand and shown limited growth potential. NMC chemistry is primarily used in power tools, e-bikes, and other electric powertrains. It stands out as the preferred battery for electric vehicles due to its combination of high capacity, high power, and low self-heating rate. It serves as a Hybrid Cell and is increasingly becoming the top choice for various applications, leading to a growing market share.

What are the key considerations for thermal runaway in these different battery types?

Considerations for thermal runaway in lithium-ion batteries vary depending on the battery type. Lithium Manganese Oxide (LMO) batteries tend to experience thermal runaway around 250°C, especially under high charge levels. In contrast, Lithium Nickel Manganese Cobalt Oxide (NMC) batteries have a lower threshold for thermal runaway at approximately 210°C. On the other hand, Lithium Iron Phosphate (LiFePO4) batteries are recognized for their superior safety features, as they exhibit a higher resilience to misuse and are less prone to thermal runaway events when compared to other lithium-ion battery systems. These differences in thermal runaway characteristics underscore the importance of understanding the unique properties and thresholds of each battery type to mitigate potential risks associated with overheating.

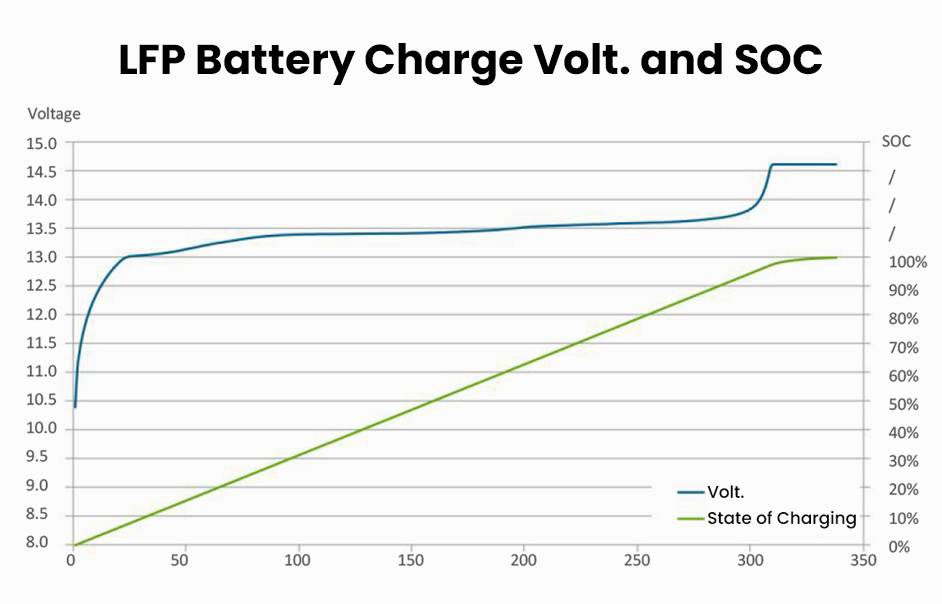

How does the charge and discharge behavior differ between LMO, NMC, and LiFePO4 batteries?

Lithium Manganese Oxide (LMO) batteries typically charge to 4.20V and discharge at 2.50V with specific charge and discharge rates. In comparison, Lithium Nickel Manganese Cobalt Oxide (NMC) batteries have different charge voltages and discharge characteristics. Lastly, Lithium Iron Phosphate (LiFePO4) batteries exhibit distinct charge and discharge behaviors compared to both LMO and NMC batteries.

What is the structure and composition of NMC batteries?

NMC batteries, short for nickel-manganese-cobalt batteries, are a type of lithium-ion battery known for their successful composition. The structure of NMC batteries typically consists of a cathode combination of nickel, manganese, and cobalt in varying proportions. This combination is often denoted as 1-1-1, indicating equal parts nickel, manganese, and cobalt. Cobalt plays a crucial role in stabilizing nickel, which is known for its high energy density as an active material in the battery.

To optimize performance while reducing reliance on cobalt, battery manufacturers have developed alternative compositions such as NCM532, which comprises 5 parts nickel, 3 parts cobalt, and 2 parts manganese. Other variations include NMC622 and NMC811, each with its specific ratios of nickel, manganese, and cobalt. These variations offer different trade-offs between performance and the use of cobalt, allowing manufacturers to tailor NMC batteries to meet specific requirements for energy density, stability, and overall battery performance.

How do NMC and Li-phosphate batteries compare in terms of voltage, specific energy, and cycle life?

NMC batteries typically have a higher nominal voltage range and specific energy capacity compared to Li-phosphate batteries. This translates to improved performance in terms of providing higher operating voltages and greater specific energy, which can influence the overall efficiency and power output of the battery system. However, Li-phosphate batteries are known for their good electrochemical performance, long cycle life, and high current rating. Despite having a lower nominal voltage, Li-phosphate batteries offer advantages such as longevity and robust performance under varying current loads. Additionally, while NMC batteries exhibit a wide operating voltage range and specific energy capacity, Li-phosphate batteries are favored for their stable and enduring cycle life, making them a reliable choice for applications requiring longevity and consistent performance over multiple charging cycles.

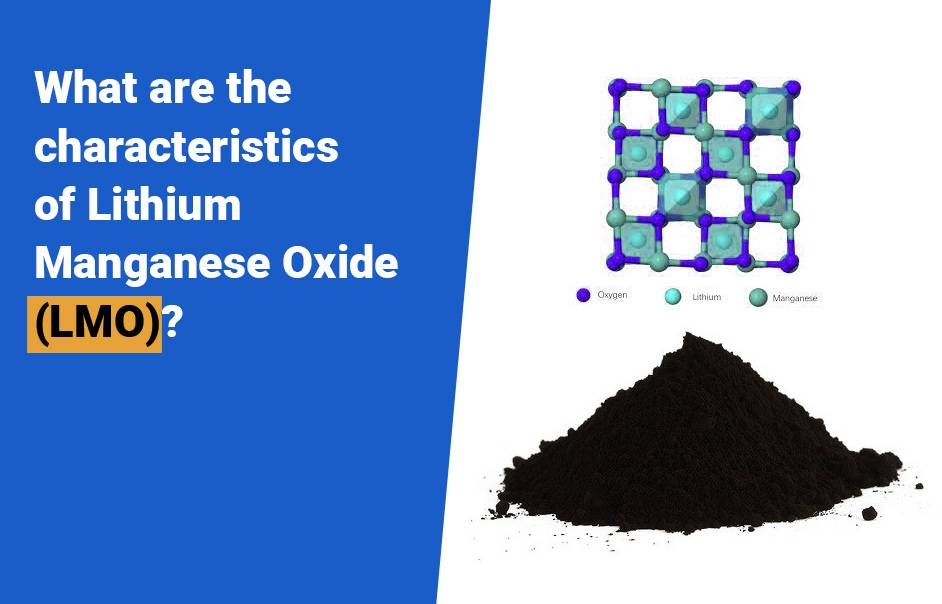

What are the characteristics of Lithium Manganese Oxide (LMO)?

Lithium Manganese Oxide (LMO) is a cathode material with a spinel structure, commonly known as LiMn2O4, and has been in use since 1996. Its nominal voltage is around 3.70V (3.80V), with an operating range typically between 3.0V and 4.2V per cell. LMO has a specific energy capacity ranging from 100 to 150Wh/kg. When charging, the typical charge rate is between 0.7 and 1C, with a maximum of 3C, reaching up to 4.20V in most cells. It is crucial to turn off the charge when the current saturates at 0.05C.

During discharge, LMO can handle rates of 1C; however, some cells can manage up to 10C, with a pulse environment allowing for bursts of up to 30C for very short durations (5 seconds). The discharge cutoff voltage is typically set at 2.50V. The cycle life of LMO is in the range of 300 to 700 cycles and is influenced by factors such as the depth of discharge and temperature. Thermal runaway, where the battery temperature increases uncontrollably, usually occurs around 250°C (482°F) and can be triggered by high charging rates.

LMO finds applications in power tools, medical devices, and electric powertrains. In recent years, LMO has been considered to have high power capabilities but lower capacity compared to other materials like Li-cobalt. To enhance performance, LMO is often combined with materials like NMC. While LMO remains strong in certain applications, it is noted that its growth potential may be limited.

What are the trends in Lithium-ion battery research and development towards improving performance, safety, and longevity for consumer and industrial applications?

In current Lithium-ion battery research and development, a key focus is on enhancing performance, safety, and longevity for both consumer and industrial applications. Researchers are exploring various approaches such as combining lithium-manganese with materials like cobalt, nickel, manganese, and aluminum in the cathode to improve battery efficiency. Additionally, the addition of silicon in small amounts to the anode has been considered to boost capacity by 25%. However, it is noted that while this enhancement increases capacity, it may impact the battery’s cycle life due to mechanical stress as silicon expands and contracts during charge and discharge cycles.

Moreover, the selection of active metals like cobalt, nickel, manganese, and silicon can be tailored to optimize specific energy (capacity), specific power (load capability), and longevity based on the intended application. For consumer applications, the emphasis is on high capacity batteries, whereas industrial needs prioritize batteries that can handle high loads, offer long service life, and maintain safety and reliability throughout their operation. This trend in research and development aims to cater to the diverse requirements of both consumer and industrial sectors by advancing lithium-ion battery technology to meet the increasing demands for performance, safety, and longevity.

How does the combination of Lithium Manganese Oxide with lithium nickel manganese cobalt oxide (NMC) enhance battery performance for electric vehicles?

The combination of Lithium Manganese Oxide with lithium nickel manganese cobalt oxide (NMC) brings significant enhancements to battery performance for electric vehicles. By blending these two materials, the specific energy of the battery is improved, leading to a longer lifespan. Integrating LMO with NMC enhances both systems’ capabilities synergistically. The LMO part of the battery, constituting around 30 percent of the overall composition, is particularly beneficial for providing a high current boost during acceleration. On the other hand, the NMC component significantly contributes to achieving an extended driving range, making it a popular choice for electric vehicles such as the Nissan Leaf, Chevy Volt, and BMW i3. This dual composition ensures that the battery performs optimally in terms of power delivery and range, making it an ideal choice for electric vehicles requiring high performance and reliability.

How do Lithium Manganese Oxide batteries achieve design flexibility in terms of capacity, longevity, and load current?

Lithium Manganese Oxide batteries achieve design flexibility by offering engineers the opportunity to optimize the battery for different purposes. This type of battery has a capacity that is slightly lower compared to other types but provides flexibility in terms of capacity, longevity, and load current. Engineers can design these batteries to prioritize either long life span, maximum load current, or high capacity, depending on the specific requirements of the application. This allows for customization to meet diverse needs in terms of energy storage, power output, and overall performance.

What are the characteristics, advantages, and limitations of Lithium Manganese Oxide (LiMn2O4) batteries?

Lithium Manganese Oxide (LiMn2O4) batteries are known for their three-dimensional spinel structure, first introduced commercially in 1996 by Moli Energy. This unique architecture enhances ion flow within the electrode, resulting in lower internal resistance and improved current handling capabilities. As a result, LiMn2O4 batteries can be rapidly charged and discharged at high currents, making them suitable for applications such as power tools, medical instruments, and hybrid/electric vehicles.

One of the key advantages of using lithium manganese oxide is its high thermal stability and enhanced safety features. Additionally, its design flexibility allows for customization based on specific needs, whether optimizing for longevity, maximizing load current, or achieving high capacity. Engineers can adjust the battery’s capacity accordingly, with the long-life version offering moderate capacity and the high-capacity version providing more storage.

However, despite these advantages, LiMn2O4 batteries do have limitations in terms of cycle and calendar life. The cycle life may be relatively limited compared to other lithium-ion battery chemistries, particularly when subjected to continuous high loads. Furthermore, the capacity of lithium manganese oxide batteries is roughly one-third lower than that of lithium cobalt batteries, which may impact their overall energy storage capabilities.

To address these limitations and enhance performance, many LiMn2O4 batteries are blended with lithium nickel manganese cobalt oxide (NMC). This combination results in improved specific energy and extended lifespan. In electric vehicles, the LMO (NMC) blend is commonly chosen due to its ability to provide high current boosts during acceleration and offer a long driving range. Despite the potential capacity boost from adding silicon to the anode, it is crucial to note that this can lead to a shorter cycle life due to the mechanical stress caused by silicon’s expansion and contraction during charge and discharge cycles.

How does Lithium Cobalt Oxide compare to other Lithium-ion chemistries like Lithium Manganese Oxide (LiMn2O4)?

Lithium Cobalt Oxide (Li-cobalt) is known for its high specific energy but offers only moderate performance in specific power, safety, and life span compared to other Lithium-ion chemistries such as Lithium Manganese Oxide (LiMn2O4). Li-cobalt is gradually falling out of favor in the battery industry due to the high cost of cobalt and the improved performance achieved by blending it with other active cathode materials, such as NMC and NCA.

In contrast, Lithium Manganese Oxide (Li-manganese) has a capacity that is roughly one-third lower than that of Li-cobalt. However, Li-manganese offers design flexibility that enables engineers to optimize batteries for specific requirements, whether it be for longevity (life span), maximum load current (specific power), or high capacity (specific energy).

Consumer batteries often prioritize high capacity, leading to a preference for Li-cobalt, while industrial applications require batteries that can handle high load currents, deliver a long service life, and ensure safety and reliability. In this context, newer Lithium-ion chemistries like NMC and NCA are gaining popularity over Li-cobalt due to their improved performance characteristics and cost-effectiveness.

How does the structure of Lithium Cobalt Oxide batteries affect their performance and limitations?

Lithium Cobalt Oxide batteries, commonly known as Li-cobalt batteries, are characterized by their high specific energy but relatively moderate performance in terms of specific power, safety, and life span. The battery comprises a cathode made of cobalt oxide and an anode composed of graphite carbon with a layered structure. The movement of lithium ions from the anode to the cathode during discharge and the reverse flow during charging define the battery’s operation. However, the structural composition of Li-cobalt batteries also introduces certain limitations. These batteries have a shorter life span, low thermal stability, and limited load capabilities or specific power. Their graphite anode, typical of cobalt-blended Li-ion batteries, contributes to challenges such as a changing solid electrolyte interface (SEI), thickening on the anode, and lithium plating, especially when subjected to fast charging and low-temperature charging conditions. These structural features significantly impact the performance and limitations of Lithium Cobalt Oxide batteries, influencing factors like cycle life, stability, and overall efficiency.

What are the specific energy, specific power, charge/discharge characteristics, cycle life, and applications of Lithium Cobalt Oxide batteries?

Lithium Cobalt Oxide batteries, also known as LCO or Li-cobalt batteries, offer specific energy ranging from 150 to 200Wh/kg, with specialty cells providing up to 240Wh/kg. These batteries have a voltage of 3.60V nominal and operate within a range of 3.0–4.2V per cell. When it comes to charge/discharge characteristics, they can typically be charged at a rate of 0.7–1C, reaching a voltage of 4.20V during charging. Discharging at a rate of 1C with a cutoff at 2.50V is recommended to maintain battery life. It’s crucial to avoid charging currents above 1C as it can lead to a shortened battery life.

The cycle life of Lithium Cobalt Oxide batteries ranges from 500 to 1000 cycles, with several factors affecting this longevity, such as depth of discharge, load, and temperature conditions. These batteries are known to experience thermal runaway at 150°C (302°F), which makes regulating charging important to prevent overheating issues. Common applications of Lithium Cobalt Oxide batteries include their usage in mobile phones, tablets, laptops, cameras, and other portable electronic devices.

What are the characteristics, advantages, and drawbacks of Lithium Cobalt Oxide (LiCoO2) batteries?

Lithium Cobalt Oxide (LiCoO2) batteries are known for their high specific energy, which makes them ideal for applications such as mobile phones, laptops, and digital cameras. These batteries consist of a cobalt oxide cathode and a graphite carbon anode. The main advantage of LiCoO2 batteries is their high specific energy, which allows for longer usage time in portable electronic devices. However, they also have drawbacks such as moderate performance specific power, safety concerns, and a relatively short life span. Additionally, LiCoO2 batteries have low thermal stability and limited load capabilities, which can affect their overall performance. Despite these drawbacks, LiCoO2 batteries remain popular due to their high energy density and suitability for mobile devices.

What are the common types of Lithium-ion batteries and their chemical symbols and abbreviations?

Lithium-ion batteries come in various types, each identified by their active materials represented by chemical symbols and abbreviations for ease of reference. One common type is lithium cobalt oxide, which is often denoted as LiCoO2 and abbreviated as LCO. This particular type is known for its high specific energy, making it a popular choice for devices like mobile phones, laptops, and cameras.

Another widely used lithium-ion chemistry is lithium manganese oxide, labeled as LiMn2O4 and abbreviated as LMO. Lithium nickel manganese cobalt oxide, known as LiNiMnCoO2 or NMC, is another common type with improved performance due to the blending of different active materials. Lithium nickel cobalt aluminum oxide, denoted as LiNiCoAlO2 or NCA, is also gaining popularity for its favorable characteristics.

Overall, these common types of lithium-ion batteries each have their unique chemical symbols and abbreviations, catering to various needs in terms of energy storage, power delivery, and longevity.

What testing and certification requirements must be met for custom lithium ion batteries?

Custom lithium ion batteries must meet various testing and certification requirements to ensure their safety and reliability. One crucial standard that custom lithium ion batteries must adhere to is UN38.3, which covers transportation safety aspects like impact, crush, and thermal testing. Additionally, these batteries need to be certified according to UL 1642 and UL 2054 standards to guarantee their safety for use in different applications. Moreover, following guidelines such as IEC 62133-2:2017 for secondary lithium ion cells and batteries in general industrial applications is essential. Manufacturers like Redway Power prioritize meeting these rigorous requirements to provide customers with high-quality and durable custom lithium ion batteries.

How long does it typically take to design and produce a custom lithium ion battery?

Designing and producing a custom lithium ion battery can vary in terms of the time it takes, as numerous factors can influence the timeline. However, by working with a reputable manufacturer like Redway Power, the process can be streamlined and efficient. The experienced team at Redway Power is dedicated to creating high-quality custom lithium ion batteries that meet the unique needs and specifications of their clients. The overall duration of the design and production stages can differ depending on the project requirements, but the company is committed to collaborating closely with clients to establish a suitable timeline. With a strong emphasis on quality and productivity, the design and production of a custom lithium ion battery can typically be completed within a matter of weeks. This quick turnaround time is coupled with the delivery of batteries that offer numerous benefits, such as high energy densities, extended lifetimes, and rapid recharging capabilities. These advanced batteries cater to a diverse range of applications across various industries, including electric vehicles, consumer electronics, and medical devices. For those seeking a reliable and experienced manufacturer for custom lithium ion batteries, Redway Power is well-equipped to not only meet but surpass expectations with their dedication to quality and efficiency.

What are the benefits of using lithium ion technology for custom battery designs?

Lithium ion technology offers numerous benefits for custom battery designs, making it a highly sought-after choice in the industry. One of the key advantages is the superior performance and durability of lithium ion batteries compared to traditional technologies. These batteries are known for their higher energy densities, longer lifetimes, and lower self-discharge rates, resulting in cost savings and improved functionality for various applications.

Furthermore, opting for lithium ion technology for custom battery designs aligns with environmental sustainability goals. Manufacturers like Redway Power prioritize eco-friendly practices by using recyclable materials in their batteries and implementing efficient manufacturing processes to reduce waste and emissions. This commitment to sustainability ensures that custom lithium ion batteries not only perform well but also have a positive impact on the environment.

In conclusion, choosing lithium ion technology for custom battery designs provides companies with a range of exceptional benefits. These batteries offer top-notch performance, durability, and efficiency while also supporting environmental sustainability efforts. Partnering with a reputable manufacturer like the Redway Power can guarantee high-quality custom lithium ion batteries tailored to specific applications, backed by expertise, cutting-edge technology, and ethical practices.

What testing and certification requirements must be met for custom lithium-ion batteries?

Custom lithium-ion batteries must meet various testing and certification requirements to ensure their safety and reliability. One crucial standard is UN38.3, which covers transportation safety aspects such as impact, crush, and thermal testing. Compliance with this standard is essential to guarantee that the batteries can be safely transported. Additionally, certification to UL 1642 and UL 2054 standards is vital to verify the batteries’ safety for a broad range of applications. These standards ensure that the batteries meet specific safety requirements for diverse uses. Adherence to IEC 62133-2:2017 guidelines is also crucial for custom lithium-ion batteries intended for general industrial applications. Overall, meeting these testing and certification requirements is paramount to ensuring the quality, safety, and longevity of custom lithium-ion batteries.

What safety standards are in place for custom lithium-ion batteries?

Custom lithium-ion batteries adhere to strict safety standards to ensure their safe use in various applications. At Redway Power, our focus on safety is paramount throughout the production process. Our batteries undergo extensive testing and quality control measures to meet or exceed industry safety standards. We incorporate high-quality components and materials that comply with regulatory requirements. Our battery designs feature essential safety mechanisms such as overcharge protection, short circuit protection, and thermal protection. Our team of skilled engineers and specialists is committed to upholding safety protocols by leveraging cutting-edge equipment and manufacturing techniques. Ultimately, our custom lithium-ion batteries prioritize safety to deliver reliable performance for diverse applications, including medical devices, power tools, electric vehicles, and beyond.

How long does it typically take to design and produce a custom lithium-ion battery?

The duration required to design and manufacture a custom lithium-ion battery can differ significantly depending on various factors. It is important to choose a reputable manufacturer who can streamline the process efficiently. At Redway Power, we specialize in creating tailored lithium-ion batteries to fulfill our clients’ specific requirements. Our skilled team of engineers and designers is dedicated to ensuring that each battery produced meets top-quality standards.

As for the typical duration for the completion of designing and manufacturing a custom lithium-ion battery with our company, it can vary based on the project’s complexity and scope. However, we always collaborate closely with our clients to establish a timeline that aligns with their needs. With a strong emphasis on both quality and productivity, we often achieve the goal of finalizing the design and production stages within a matter of weeks.

What are the benefits of using lithium-ion technology for custom battery designs?

Lithium-ion technology offers numerous benefits for custom battery designs. Custom lithium ion batteries are known for their superior performance and durability, providing cost savings and enhanced functionality. Compared to traditional battery technologies, lithium-ion batteries boast higher energy densities, longer lifetimes, and lower self-discharge rates. These characteristics make them an excellent choice for applications requiring reliable and long-lasting power sources.

Furthermore, lithium-ion technology aligns with environmental sustainability goals. Companies like Redway Power prioritize eco-friendliness by designing batteries that meet stringent environmental regulations and standards. The materials used in lithium-ion batteries are recyclable, and the manufacturing process is highly efficient, aimed at minimizing waste and emissions. By opting for lithium-ion technology in custom battery designs, businesses can benefit from high performance, durability, and environmental responsibility.

What is the warranty information provided for the battery?

The warranty information provided for the battery states that it is warranted to be free from defects in materials and workmanship under everyday use and service for a 5-year period from the date of sale. Customers can determine the date of sale using their sale receipt, shipping invoice, or the battery serial number with proof of purchase. The warranty information directs customers to visit the Warranty Policy Page for more details.

What are the discharge specifications of the battery?

The discharge specifications of the battery include details such as the maximum continuous discharge current, peak discharge current, discharge over-current protection, recommended low voltage disconnect, discharge under-voltage protection, reconnect voltage, and short circuit protection response time. These specifications provide important information about how the battery can be safely discharged and protected against various conditions during use.

What are the electrical specifications of the battery?

The electrical specifications of the battery include details pertaining to its electrical performance and characteristics.

1. **Nominal Voltage:** This refers to the typical voltage at which the battery operates. It is a standard value used to describe the voltage output of the battery under normal operating conditions.

2. **Nominal Capacity:** The nominal capacity of the battery is the amount of charge it can store and deliver. This is usually expressed in ampere-hours (Ah) or milliampere-hours (mAh), and it indicates how long the battery can power a device at a specific current draw.

3. **Energy:** The energy of the battery is the total amount of energy it can store and provide. This is typically measured in watt-hours (Wh) or kilowatt-hours (kWh), representing the overall energy capacity of the battery.

4. **Efficiency:** The efficiency of the battery describes how effectively it can convert stored energy into usable electrical power. Higher efficiency means less energy is wasted as heat during charging and discharging processes.

5. **Resistance:** Battery resistance refers to the opposition the battery presents to the flow of electrical current. Lower resistance typically means better efficiency and performance of the battery.

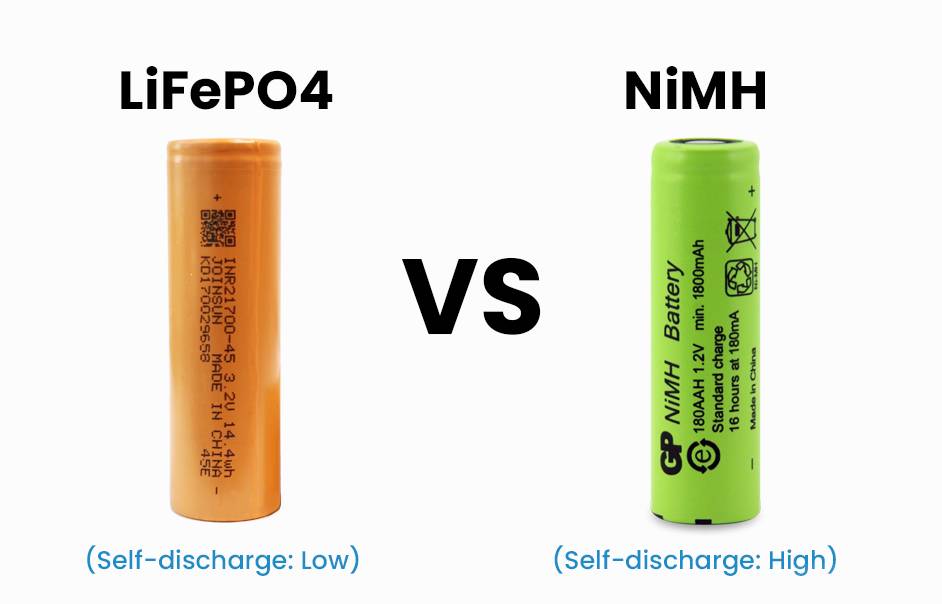

6. **Self Discharge:** Self-discharge is the rate at which a battery loses its charge when not in use. It is an important consideration for batteries that are used infrequently or stored for extended periods.

Additionally, the battery holds various certifications including UN38.3, CE, UL1642, and IEC62133, which indicate compliance with specific safety and performance standards. Its shipping classification is UN3480, CLASS 9, which is essential information for the safe transportation of the battery.

What services does Redway Power offer for creating custom lithium ion batteries?

Redway Power offers a comprehensive range of services for creating custom lithium ion batteries tailored to meet the specific needs of its clients. These services include battery design and testing, prototyping, assembly, and mass production. The company leverages over a decade of industry experience to deliver high-quality, reliable, and efficient batteries. Their team of experts is dedicated to providing personalized solutions that align with each customer’s unique requirements. Redway Power utilizes cutting-edge technology and equipment to ensure that every battery is manufactured to the highest standards of quality and performance. The custom lithium ion batteries offered by the company are known for their superior durability and performance, leading to enhanced functionality and cost savings for clients in industries such as consumer electronics and medical devices.

Who are the trusted partners of Redway Power?

The trusted partners of Redway Power are those who use LBC’s batteries to power their products. They are announced with pride by the company.

What services does Redway Power offer for creating custom lithium-ion batteries?

Redway Power specializes in offering a comprehensive array of services dedicated to the creation of custom lithium-ion batteries. With a strong focus on meeting the unique requirements of each client, the company provides a range of services that encompass the entire battery development process. This includes battery design and testing, prototyping, assembly, and large-scale production. By leveraging cutting-edge technology and equipment, Redway Power ensures that every battery it produces adheres to the highest standards of quality and performance. With over a decade of experience in the industry, the company has established itself as a trusted partner for a diverse range of industries, from consumer electronics to medical devices, seeking top-notch custom lithium-ion battery solutions.

How can customers design their custom battery with Redway Power?

Customers can design their custom battery with Redway Power by leveraging the company’s expertise in providing powerful, customized lithium ion batteries for various applications. With over 11 years of experience, the company places an emphasis on safety and efficiency in battery design to prevent malfunctions and unexpected power failures. Throughout the process, customers receive personalized attention and guidance from the company’s team, starting from the initial design consultation all the way to production and delivery.

One of the key features of the custom lithium-ion batteries offered by Redway Power is their high energy density, allowing them to store more energy in a given space. These batteries also boast a longer lifespan compared to other types of batteries, requiring minimal maintenance and reducing costs over the battery’s lifetime. Moreover, lithium-ion batteries are known for being smaller and more powerful, making them ideal for applications that require lightweight and compact power solutions. Customers also benefit from the fast-charging capabilities of lithium-ion batteries, enabling quick charging to full capacity.