Blog

How to Change a Forklift Battery: Step-by-Step Guide

Changing a forklift battery involves parking the forklift securely, disconnecting the old battery safely, using appropriate lifting equipment to remove and replace the battery, and reconnecting everything carefully while following safety protocols. Proper procedure ensures operator safety, battery longevity, and forklift reliability.

How Do You Prepare for Changing a Forklift Battery?

Begin by parking the forklift on a flat, stable surface and turning off the ignition. Engage the parking brake and remove the key. Equip yourself with proper personal protective equipment such as insulated gloves and safety goggles. Ensure the area is well-ventilated to avoid hazard buildup during battery handling.

How Should You Disconnect the Old Battery Safely?

Disconnect the battery’s electrical connectors, starting with the negative terminal to prevent short circuits. Remove any securing mechanisms or clamps holding the battery in place. Check cables and connectors for wear or corrosion and handle the battery with care to prevent damage or leaks.

What Equipment Is Needed to Remove and Transport the Forklift Battery?

Use specialized lifting equipment such as battery lifting beams, hoists, or carts designed for forklift battery handling. This prevents strain injuries and reduces the risk of dropping or damaging the battery during transfer.

How Do You Install the New Battery Correctly?

Position the new battery into the forklift battery compartment carefully, ensuring proper alignment with connectors and securing clamps. Connect the positive terminal first followed by the negative. Tighten terminals securely and inspect all connections to ensure safety and operational reliability.

What Safety Checks Should Be Conducted After Changing the Battery?

Check for secure mounting, correct cable connections, and absence of corrosion. Test the forklift by powering it on and observing battery indicators for correct functionality. Also, verify ventilation and compliance with local safety regulations during operation.

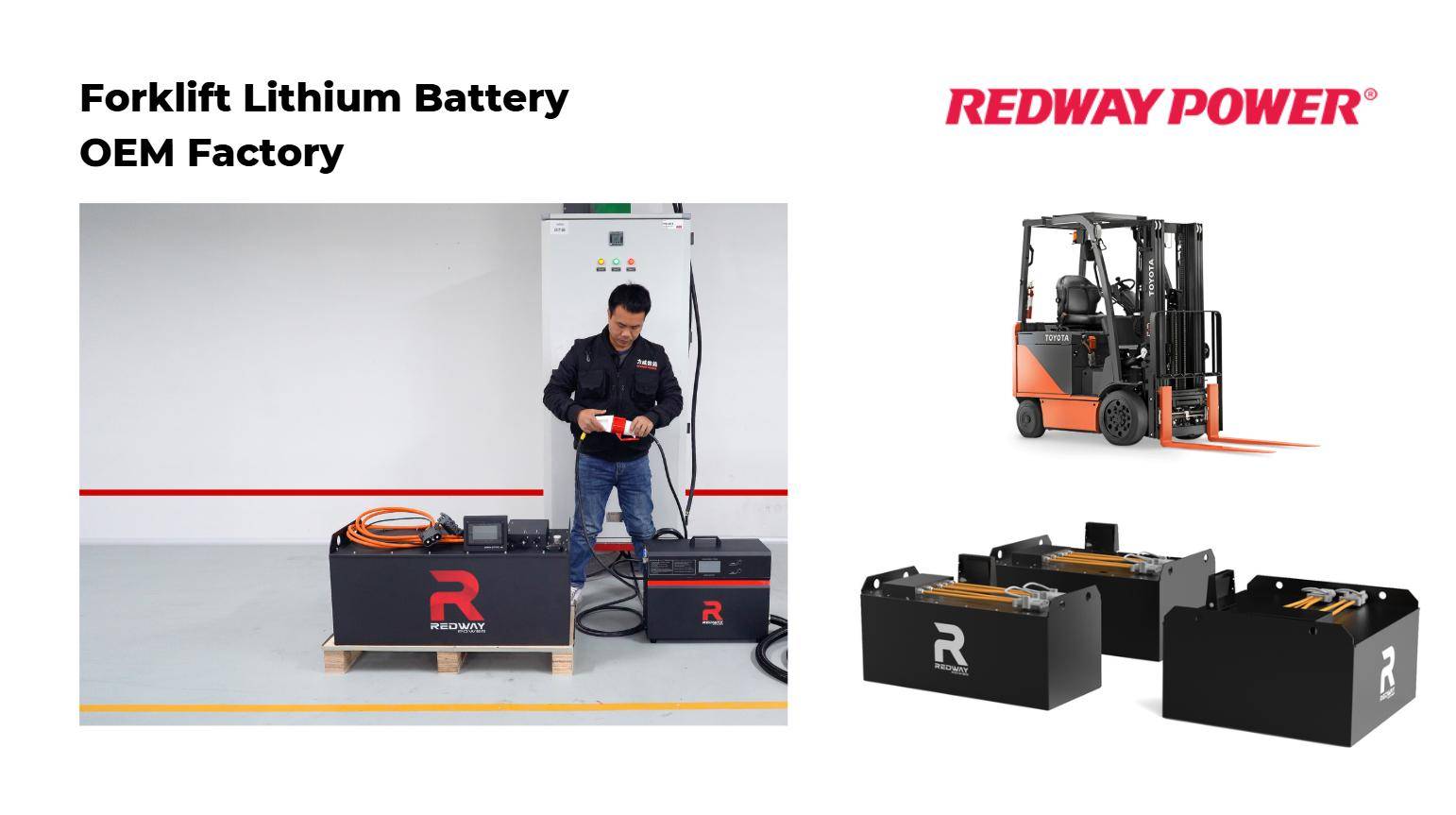

How Can Redway Power Products Facilitate Safe and Efficient Battery Changes?

Redway Power designs forklift batteries with standardized dimensions and integrated BMS systems to simplify safe installation and ensure consistent performance. Their ISO 9001:2015 certified manufacturing and MES technology guarantee battery quality, durability, and operational safety.

Battery Change Step-by-Step Chart

| Step | Action | Safety Tip |

|---|---|---|

| Preparation | Park forklift & PPE use | Ensure area ventilation |

| Disconnecting Battery | Remove negative then positive | Avoid short circuits |

| Battery Removal | Use proper lifting equipment | Prevent battery drops and injury |

| Installing New Battery | Secure and connect terminals | Tighten connections properly |

| Safety Inspection | Test forklift and verify status | Confirm no leaks or faults |

Redway Power Expert Views

“Changing forklift batteries correctly is crucial for operator safety and operational efficiency. Redway Power’s precision-engineered lithium-ion battery packs integrate advanced safety features that simplify handling and installation while maximizing performance and lifespan in industrial settings.” — Redway Power Technical Expert

Conclusion

Changing a forklift battery requires meticulous steps involving preparation, safe disconnection, use of specialized lifting equipment, precise installation, and thorough safety checks. Following these steps with trusted OEM products from manufacturers like Redway Power ensures safe, efficient battery swaps that maintain forklift reliability and workplace safety.

FAQs

What is the safest way to disconnect a forklift battery?

Always disconnect the negative terminal first to avoid short circuits.

What equipment is necessary for removing a forklift battery?

Use battery lifting beams, hoists, or carts designed for battery transport.

How do you ensure the new battery is installed correctly?

Align it properly, secure clamps, and connect terminals positive first, then negative.

Why is PPE important when changing forklift batteries?

PPE protects against chemical exposure and electrical hazards.

Can Redway Power batteries help simplify battery changes?

Yes, they are designed for safe handling with integrated safety and quality controls.