Lead-acid batteries, enduring power sources, consist of lead plates in sulfuric acid. Flooded and sealed types serve diverse applications like automotive and backup power. Maintenance, proper testing, and cautious restoration techniques can extend their lifespan. Use lithium-specific chargers to avoid damage. Safety first!

What are lead acid batteries?

Lead-acid batteries are a type of rechargeable battery that has been around for over 150 years. They consist of lead plates submerged in sulfuric acid electrolyte, enclosed in a plastic casing. These batteries are known for their reliability and affordability, making them popular in various applications.

There are two main types of lead-acid batteries: flooded (wet cell) and sealed (valve-regulated lead-acid or VRLA). Flooded batteries require regular maintenance to top up the electrolyte levels, while sealed batteries are maintenance-free and commonly used in UPS systems and solar power storage.

Lead-acid batteries (AGM and GEL) have a relatively low energy-to-weight ratio compared to other battery types like lithium-ion. However, they excel in providing high surge currents, making them ideal for starting vehicles and powering backup systems when needed.

What are lead acid batteries used for?

Lead-acid batteries have diverse uses across industries. They power vehicles like cars, trucks, and boats, while also serving as backup energy sources for homes and businesses during power outages. Additionally, they store energy in off-grid solar setups and support emergency lighting systems. Lead-acid batteries are essential for uninterrupted power supply and renewable energy applications.

Lead-acid batteries have various uses across different areas. Let’s break down their importance in simple terms:

- Versatile Power Source: Lead-acid batteries are like the Swiss Army knives of power storage. They’re used in vehicles, homes, and businesses for different purposes.

- Automotive Power: Cars, trucks, boats, and motorcycles rely on lead-acid batteries to start their engines and power accessories like lights and radios.

- Backup Energy: During power outages, these batteries kick in to provide electricity for essential appliances, ensuring homes and businesses stay functional.

Understanding the versatility of lead-acid batteries helps us appreciate their significance in our daily lives.

How do lead acid batteries work?

Lead-acid batteries, like car batteries, work by converting chemicals into electricity. Inside, there are lead plates and sulfuric acid in water. When charged, a chemical reaction happens, producing electricity. During use, the battery releases stored energy. Recharging reverses the process. These batteries are great for short bursts of power, like starting cars, but not for continuous use. Regular maintenance is important for longer life.

Lead-acid batteries, commonly found in cars and emergency power supplies, operate using a simple chemical process to produce electricity. Here’s how they work:

- Components: Lead-acid batteries contain lead plates immersed in sulfuric acid and water. One plate is coated with lead dioxide, while the other is pure lead.

- Chemical Reaction: Charging the battery causes a chemical reaction where lead dioxide reacts with sulfuric acid to form lead sulfate and release electrons. This process occurs on both plates, generating electricity.

- Discharge and Recharge: When the battery discharges, the lead sulfate breaks down back into lead dioxide and pure lead, releasing electrons to power devices. Recharging the battery reverses this process, restoring its energy storage capacity.

Remember, lead-acid batteries are best for short bursts of power, like starting a car, and require regular maintenance to prolong their lifespan.

How to test a sealed lead acid battery?

To test a sealed lead acid battery, use a multimeter to measure its voltage. Ensure it’s fully charged and rested. Set the multimeter to DC voltage mode, then place the probes on the battery terminals. Readings below 12.6 volts may indicate the battery needs charging or replacing. Consult a professional if needed for further evaluation.

Testing a sealed lead acid battery is crucial for ensuring its performance. Here’s how:

- Use a Multimeter: A multimeter is a handy tool for measuring the battery’s voltage, indicating its charge level accurately.

- Check Voltage: Ensure the battery is fully charged and rested. Place the multimeter probes on the battery terminals to read the voltage.

- Interpret Readings: Readings below 12.6 volts may suggest the battery needs charging or replacing. Consulting a professional can provide further insights if needed.

Regular testing helps maintain the battery’s efficiency and longevity, ensuring reliable performance when needed.

How to open a sealed lead acid battery?

Wondering how to open a sealed lead acid battery? With the right tools like safety goggles and a screwdriver, it’s manageable. Carefully pry open the plastic caps covering the cells, avoiding damage to the battery. Then, handle the electrolyte solution inside with caution. Following these steps ensures safe and effective battery access for testing or maintenance purposes.

Opening a sealed lead acid battery may seem challenging, but it’s manageable with the right approach:

- Gather Tools: Ensure you have safety goggles, gloves, and a screwdriver ready for the task.

- Careful Inspection: Examine the battery casing for any damage or leakage before proceeding.

- Methodical Approach: Use the screwdriver to gently pry open the plastic caps covering the cells, avoiding any damage to the battery.

- Handle Electrolyte with Caution: Once opened, handle the electrolyte solution inside carefully to prevent spills and accidents.

Following these steps ensures safe and effective access to the battery for testing or maintenance purposes.

Maintenance Tips for Prolonging Battery Life

Keep your battery in top shape with these easy maintenance tips:

- Check and top up electrolyte levels regularly.

- Clean terminals to prevent corrosion.

- Avoid overcharging or deep discharging.

- Store in a cool, dry place.

- Use a suitable charger.

- Test battery capacity periodically.

- Consider a desulfator for better performance.

Can you charge a lithium battery with a lead acid charger?

Charging a lithium battery with a lead acid charger can be risky. Lithium batteries need specific charging parameters. Using a lead acid charger may lead to overcharging or undercharging, damaging both the battery and the charger. It’s safer to use a charger designed for lithium batteries to prevent damage and ensure proper charging.

When it comes to charging lithium batteries with a lead acid charger, it’s important to know the risks.

- Different Requirements: Lithium batteries need specific charging parameters unlike lead-acid batteries due to their higher energy density.

- Safety Concerns: Using a lead acid charger for lithium batteries can lead to undercharging or overcharging, which can damage both the battery and the charger.

- Recommendation: To avoid risks, it’s best to use a charger designed specifically for lithium batteries to ensure safe and efficient charging.

Remember, following manufacturer recommendations is crucial for battery safety and performance.

How to restore lead acid battery?

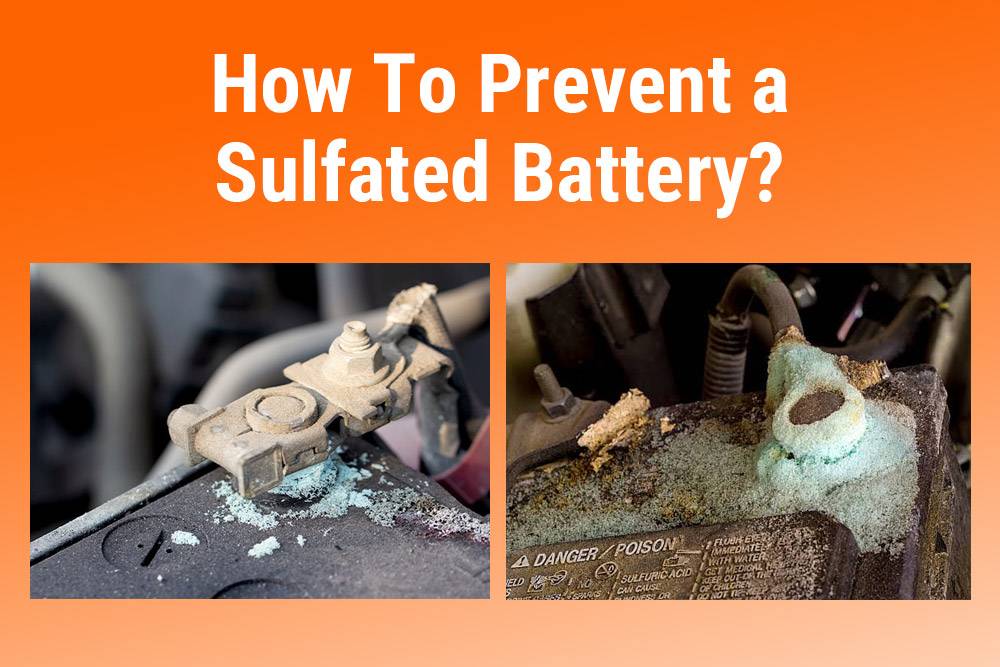

Restoring a lead-acid battery can boost its performance and lifespan. One method is equalization charging, applying a controlled overcharge to break down sulfation. Alternatively, desulfation devices or additives dissolve sulfate crystals on battery plates. Note, severe damage may render restoration ineffective. Assess battery condition before attempting restoration.

Restoring a lead-acid battery can be a great way to make it work like new again. Here’s how:

- Equalization Charging: This involves giving the battery a controlled overcharge to break down sulfation, a common cause of battery deterioration.

- Desulfation Devices/Additives: These are products designed to dissolve sulfate crystals on the battery plates, improving its ability to hold a charge.

- Assess Battery Condition: Not all batteries can be restored, especially if they’re severely damaged. It’s important to check the battery’s condition before attempting any restoration methods.

By following these steps, you can potentially extend the life of your lead-acid battery and improve its performance.

How to rejuvenate a lead acid battery?

Learn how to rejuvenate a lead-acid battery with simple steps. Proper maintenance and testing can extend battery life. While using a lead-acid charger for lithium batteries is not recommended, methods like desulfation or additives can restore lead-acid batteries. Follow safety guidelines and seek professional help if needed for effective battery management and longevity.

Lead-acid batteries are used in various devices like cars and backup systems. Learning how to rejuvenate them is crucial for extending their lifespan and maintaining performance.

- Simple Steps: Rejuvenating a lead-acid battery involves straightforward processes like cleaning the cells, checking voltage, and fully charging and discharging the battery.

- Proper Techniques: While using a lead-acid charger for lithium batteries isn’t safe, methods like desulfation or additives can effectively restore lead-acid batteries.

- Safety First: Always prioritize safety when working with batteries and seek professional guidance if needed to ensure effective management and longevity.