Here we talk about what are cold cranking amps in a battery, and differences between cold cranking and cranking amps. Actually, converting Cold Cranking Amps (CCA) to Amp Hours (Ah) involves using formulas. CCA measures power for starting engines, while Ah indicates overall capacity. Lead-acid and lithium batteries differ in conversion and application due to chemistry. Both metrics assess battery capacity, with CCA emphasizing quick bursts and Ah measuring capacity over time.

Converting Cold Cranking Amps (CCA) to Amp Hours (Ah) isn’t a simple one-to-one process due to a fundamental distinction between the two metrics. CCA assesses a battery’s capability to deliver robust currents necessary for starting internal combustion engines, usually within a 30-second timeframe. Conversely, Ah indicates the battery’s capacity to provide a specific current over an extended period, typically 20 hours.

In essence, while both CCA and Ah reflect the battery’s capacity and its ability to supply current, they do so in different contexts. CCA emphasizes quick bursts of power for engine starting, while Ah measures the overall capacity over a longer timeframe.

What is Cold Cranking Amps (CCA)?

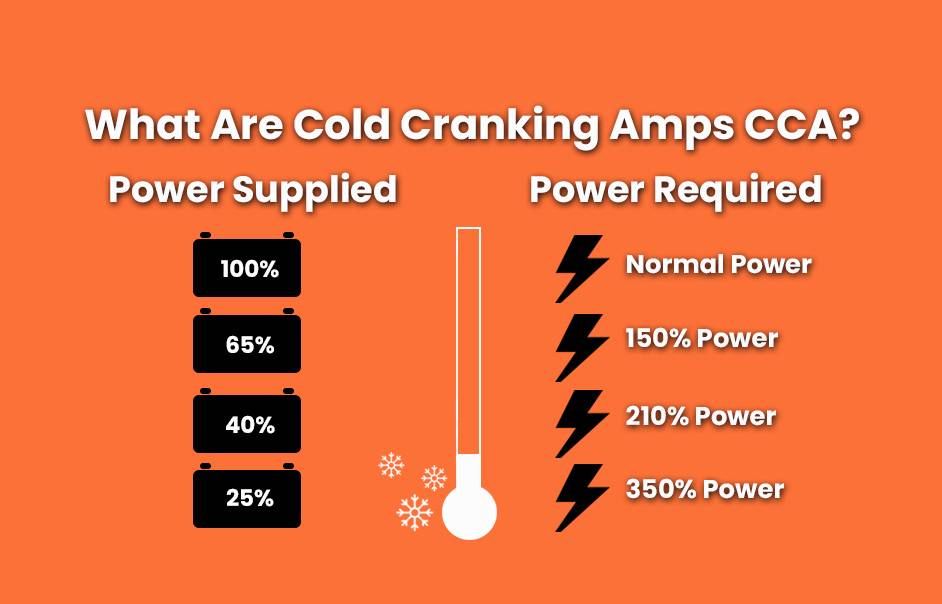

Cold Cranking Amps (CCA) measures a battery’s capacity to deliver current in cold weather, crucial for starting a vehicle’s engine. It indicates the maximum current a battery can provide for around 30 seconds at 0°F (-18°C) while maintaining a voltage above a specified threshold. Higher CCA ratings ensure reliable engine starting in cold climates. This can explain what does cold cranking amps (CCA) mean or

what do cold cranking amps (CCA) measure.

The CCA rating is crucial for starting internal combustion engines in cold weather conditions when the engine oil may be thick and resistant to flow, requiring more power to turn the engine over. Higher CCA ratings indicate batteries that can deliver more power and are better suited for cold weather starting.

Overall, CCA provides an essential measure of a battery’s ability to start an engine reliably in cold climates, making it a crucial consideration when selecting a battery for vehicles operating in such conditions.

What is Amp Hours (Ah)?

Amp Hours (Ah) measures a battery’s energy storage capacity over time, indicating the charge it can deliver in one hour at a given rate. For example, a 50 Ah battery sustains a 50-ampere current for an hour. Commonly used in deep-cycle batteries for marine and solar systems, Ah offers crucial insight into sustained energy delivery.

Amp Hours is commonly used to describe the capacity of deep-cycle batteries, such as those used in marine, RV, and solar power systems, where sustained and steady energy delivery is important over longer periods.

In summary, Amp Hours provides a measure of a battery’s total energy storage capacity, indicating how long it can sustain a specific electrical load before needing to be recharged.

Cold Cranking Amps (CCA) vs Cranking Amps (CA), What are the Differences?

Cranking Amps (CA) measures starting power at 32°F, while Cold Cranking Amps (CCA) evaluates it at 0°F. CA tells you how much power your battery can provide at a moderate temperature, while CCA assesses its performance in cold weather. Higher CCA ratings mean better starting power in freezing temperatures.

Understanding the difference between Cold Cranking Amps (CCA) and Cranking Amps (CA) helps you know how your car battery works better.

- Cranking Amps (CA):

- CA measures how much power your battery can give at a normal temperature of 32°F.

- It’s like checking if your battery can handle starting your car on a regular, not-too-cold day.

- Cold Cranking Amps (CCA):

- CCA, on the other hand, shows how well your battery can start your car when it’s freezing at 0°F.

- It’s like testing if your battery can handle the chill and still kickstart your car into action.

- Choosing the Right Battery:

- If you live in a place where it gets super cold, like Alaska or Canada, you’ll want a battery with a high CCA rating to make sure your car starts smoothly even in freezing weather.

- So, remember, CA checks regular starting power, while CCA tests it in icy conditions!

Understanding these ratings helps you pick the perfect battery for your car and ensures you’re ready for any weather.

How Many Cold Cranking Amps Do You Need?

Cold Cranking Amps (CCA) measures a battery’s ability to start a car in cold weather. It’s vital because cold temperatures slow battery reactions, making starting harder. Choosing a battery with sufficient CCA for your climate is crucial. Higher CCA means better performance in the cold, ensuring reliable starts. Consider climate and driving habits when selecting to keep your engine running smoothly.

Understanding car batteries and their Cold Cranking Amps (CCA) is like knowing the superhero strength of your car. It’s the power it needs to wake up, especially in chilly weather!

- CCA, the Car’s Wake-Up Power:

- Think of CCA as the energy your car needs to kickstart its engine when it’s super cold outside.

- It’s measured in amps, like the battery’s muscles, ensuring it can start your car even when it’s freezing.

- Why CCA Matters:

- Imagine you’re in a race but your legs are frozen solid – that’s what happens when your car’s CCA isn’t enough for the cold.

- Having the right CCA means your car can jump into action, no matter how chilly it gets outside.

- Picking the Perfect Battery:

- It’s like finding the perfect match for your car’s energy levels – not too much, not too little.

- Depending on where you live and how often you drive, you’ll need a battery with just the right CCA to keep your car roaring to life, even on the coldest mornings.

So, think of CCA as your car’s secret weapon against the cold. With the right CCA, your car will always be ready to hit the road, no matter how frosty it gets outside!

Factors that can impact CCA (Cold Cranking Amps) requirements

Discover factors impacting Cold Cranking Amps (CCA): Cold weather slows battery reactions, affecting starting power. Older batteries lose capacity, impacting cranking ability. Maintenance, like cleaning terminals and proper charging, ensures optimal performance. Understanding these factors helps choose the right battery for reliable starts, even in challenging conditions!

Understanding what affects CCA requirements helps you keep your car running smoothly, especially during cold weather.

- Temperature Impact:

- When it’s freezing outside, batteries have a tough time starting cars because their chemical reactions slow down.

- This means your battery might struggle to provide enough power to start your car in chilly temperatures.

- Battery Age Matters:

- As batteries get older, they lose their ability to hold as much charge, which can affect how well they start your car.

- If your battery is getting up there in age, it might be time to think about replacing it to ensure reliable starts.

- Importance of Maintenance:

- Taking good care of your battery is crucial for keeping it in tip-top shape.

- Regularly cleaning the terminals, checking electrolyte levels (for non-sealed batteries), and making sure it’s properly charged can help maintain optimal performance.

Conclusion: By understanding these factors and taking proper care of your battery, you can ensure that your car starts reliably, even in the coldest of temperatures!

Choose appropriate CCA for different vehicles

Ensure reliable starts by choosing the right Cold Cranking Amps (CCA) for your vehicle. Check your car manual or consult experts for recommendations based on engine size. Consider climate; colder regions may need higher CCA. Tailor CCA to your vehicle’s usage and battery class for optimal performance.

Let’s break down how to choose the right Cold Cranking Amps (CCA) for your car in simple terms, as picking the correct CCA is crucial for starting your car smoothly, especially in chilly weather.

- Consult Your Manual or Experts:

- Your car’s manual or auto professionals can recommend the ideal CCA based on your engine size.

- They have the expertise to guide you in selecting the right CCA for your vehicle’s needs.

- Consider Climate Conditions:

- If you live in a cold area, opt for a higher CCA to ensure your car starts reliably, even in freezing temperatures.

- Cold weather can affect battery performance, so having sufficient CCA is essential for hassle-free starts.

- Tailor CCA to Your Usage and Battery Class:

- Think about how you use your vehicle; short trips may require higher CCA to compensate for less charging time.

- Also, consider your vehicle’s battery class for tax purposes, as this can impact CCA needs and calculations.

By following these steps, you can choose the right CCA for your car, ensuring it starts smoothly, no matter the weather or driving conditions!

How to Test CCA and CA for Car Battery

Test Cold Cranking Amps (CCA) and Cranking Amps (CA) for your car battery: Set your battery tester to CCA mode, input the battery’s CCA rating, and check the displayed CCA value for cold weather starting power. Use a multimeter to measure voltage and discharge time while starting the engine. Ensure reliable starts by testing both CCA and CA!

How to Test CCA (Cold Cranking Amps)

Test your car battery’s Cold Cranking Amps (CCA) for reliable performance. Use a CCA-specific battery tester to load it with half its CCA for 15 seconds at 10°C (50°F) or higher. Pass if voltage stays above 9.6V. Alternatively, measure cranking current with a multimeter; if close to rated CCA, your battery is good. Regular testing ensures dependable starts!

- Use a Battery Tester:

- Connect a CCA-specific battery tester to your car battery.

- Load it with half its CCA rating for 15 seconds at 10°C (50°F) or higher.

- Pass if the voltage remains above 9.6V, indicating a healthy battery.

- Try a Multimeter:

- Set your multimeter to the amp setting.

- Measure the cranking current while starting the engine.

- If it’s close to the battery’s CCA rating, your battery is likely in good condition.

Regular testing ensures your car starts smoothly whenever you need it!

How to Test CA (Cranking Amps)

Test your car battery’s Cranking Amps (CA) using a multimeter: Turn off accessories, locate terminals, set the multimeter to DC voltage (over 20V), connect probes to terminals, and observe voltage. Ensure the reading meets or exceeds the original battery’s rating for optimal performance.

- Prepare Your Vehicle: Turn off all electrical accessories.

- Locate Battery Terminals: Find the positive (+) and negative (-) terminals.

- Set Up the Multimeter: Choose a DC voltage setting higher than 20 volts.

- Connect the Multimeter: Attach the probes to the battery terminals.

- Read the Voltage: Turn on the multimeter to observe the CA reading. Ensure it meets or exceeds the original battery’s rating for optimal performance.

Factors That Affect CCA and CA

Factors affecting Cold Cranking Amps (CCA) include temperature, battery age, and vehicle size. Colder weather demands higher CCA for optimal performance, while aging batteries lose capacity over time. Larger vehicles require more starting power, necessitating higher CCA ratings. Understanding these factors ensures reliable starts in any weather condition and prolongs battery lifespan.

Factors affecting Cranking Amps (CA) for car batteries include temperature, battery age, and vehicle size. Cold weather diminishes CA, while older batteries lose capacity. Larger engines necessitate higher CA ratings. Prioritizing maintenance ensures optimal CA for reliable starts. Explore more on How do you manually check battery health?

CCA to Ah Converter Calculator

CCA measures a battery’s power output in cold weather for engine starting, while Ah quantifies its capacity over time. Converting CCA to Ah depends on battery type and use—starting, dual-purpose, or deep cycle—each with distinct characteristics. Use battery-specific converters for accurate results.

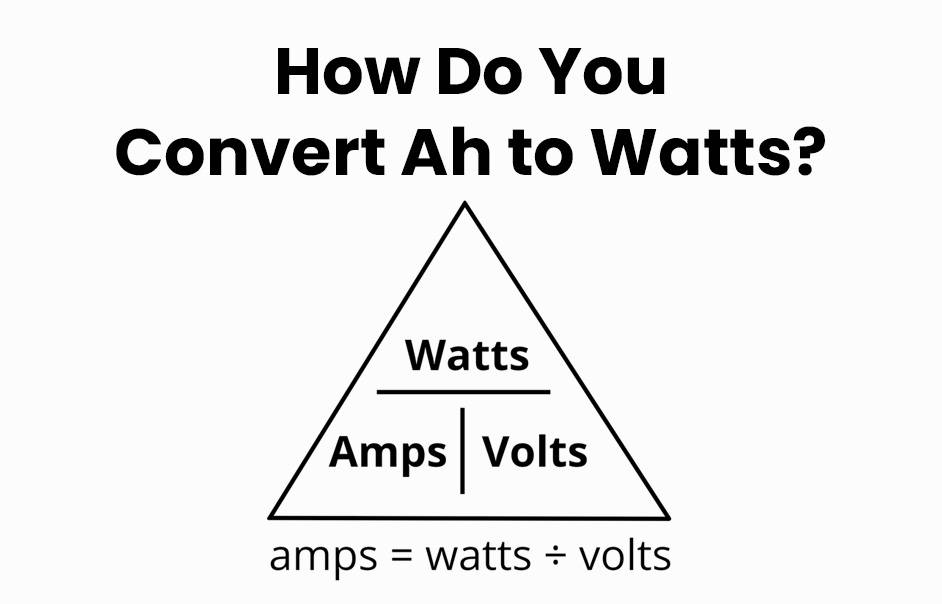

Converting Cold Cranking Amps (CCA) to Amp Hours (Ah) requires knowing the battery’s voltage. Use the formula:

Ah = (CCA * Reserve Capacity) / (60 * Voltage)

For example, if a 12V battery has a CCA of 600 and a Reserve Capacity of 120 minutes:

Ah = (600 * 120) / (60 * 12) = 100 Ah

The capacity of a fully charged 12V lead-acid battery is determined by its ability to sustain a constant discharge current for 20 hours without its voltage dropping below 10.5V, typically at a temperature of 80°F (~27°C). This capacity is then expressed as Amp Hours (Ah) by multiplying the discharge current by 20 hours.

For example, if a lead-acid battery can deliver 5 Amps for 20 hours, its capacity would be 100 Ah.

Similarly, lithium and similar batteries have their capacity defined by the continuous discharge current they can maintain for approximately 20 hours without the voltage falling below the specified cut-off voltage. It’s important to note that different manufacturers may provide capacity values for various timeframes such as 1h, 5h, or 10h, so exact specifications should be verified.

Converting Cold Cranking Amps (CCA) to Amp Hours (Ah) depends on factors like battery model, chemistry, and intended use. Various types of batteries, including starting, dual-purpose, and deep cycle batteries, each have specific characteristics designed to meet different needs.

Starting batteries are primarily used for automotive applications to crank engines and supply power to lighter loads like lights and audio systems when the engine is not running. They have thin plates optimized for high currents required during engine starts, making them unsuitable for deep cycle applications.

Dual-purpose batteries offer a compromise between starting and deep cycle capabilities. They serve as cranking batteries for engine starts while tolerating deep-cycle usage, making them versatile for various applications.

Deep cycle batteries are specifically designed for deep discharge and cycle applications. They prioritize endurance over delivering strong currents, making them ideal for sustained power delivery and frequent charging and discharging cycles.

Cold Cranking Amps (CCA) to Amp Hours (Ah) Cross Reference Chart

A Cold Cranking Amps (CCA) to Amp Hours (Ah) Cross Reference Chart displays the relationship between CCA and Ah ratings for different battery groups. It provides CCA and Ah values for various battery types, such as starting/cranking and dual-purpose batteries, helping users choose the appropriate battery for their needs based on their CCA and Ah requirements.

Below is a cross-reference chart showing average Cold Cranking Amps (CCA) and Amp Hours (Ah) values for starting, dual-purpose, and deep cycle batteries used in applications such as cars, RVs, marine vessels, and light industrial equipment, organized by their BCI group:

| BCI Battery Group | Starting / Cranking | Dual Purpose | Deep Cycle |

| Group 8D | – | 220 Ah, 1450 CCA | 250 Ah, – |

| Group 22NF | 55Ah, 500 CCA | 60Ah, 745 MCA | 55 Ah, – |

| Group 24 | – | 76 Ah, 840 CCA | 85 Ah, – |

| Group 26 | 50Ah, 550 CCA | – | – |

| Group 27 | – | 90 Ah, 900Ah | 100Ah, – |

| Group 31 | – | 100 Ah, 1000 CCA | 120 Ah, – |

| Group 34/78 | 50 Ah, 800 CCA | 65 Ah, 850 CCA | – |

| Group 35 | 44 Ah, 720 CCA | 60 Ah, 740 CCA | – |

| Group 47 (H5, L2, 55L2) | 60 Ah, 600 CCA | 50 Ah, – | – |

| Group 48 (H6, L3, 66L3) | 70 Ah, 760 CCA | 70 Ah, 750 CCA | – |

| Group 49 (H8, L5, 88L5) | 92 Ah, 850 CCA | 90 Ah, 850 CCA | – |

| Group 51 (51R) | – | 60 Ah, 700 CCA | 60 Ah, – |

| Group 58 (58R) | 50Ah, 550 CCA | – | – |

| Group 65 | – | 75 Ah, 850 CCA | – |

| Group 75 | 55 Ah, 760 CCA | 55 Ah, 750 CCA | – |

| Group 94R | – | 80 Ah, 800 CCA | – |

| Group YTX5L-BS | 4 Ah, 70 CCA | – | – |

| Group YTX20L-BS | 18 Ah, 270 CCA | – | – |

| Group YTX24HL-BS | 21 Ah, 330 CCA | – | – |

| Group YTX30L-BS | 30 Ah, 385 CCA | – | – |

Note:

The provided formats are generally true for lead-acid batteries and are used to estimate the Cold Cranking Amps (CCA) based on the Amp Hours (Ah) capacity. However, they may not directly apply to lithium batteries due to differences in chemistry and construction.

In general, the relationship between Cold Cranking Amps (CCA) and Amp Hours (Ah) depends on the battery type and typically follows these general trends:

– starting lead-acid batteries: Capacity (Ah) x (12 to 16 times) = CCA (Amps)

– dual-purpose lead-acid batteries: Capacity (Ah) x (8 to 12 times) = CCA (Amps)

– deep-cycle lead-acid batteries: Capacity (Ah) x (4 to 8 times) = CCA (Amps)

Note: Many manufacturers officially restrict the maximum current of their deep-cycle batteries, emphasizing that they are not intended for high current applications.

However, it’s essential to recognize that these relationships are approximate guidelines. Actual values can vary based on battery construction, chemistry, and specific manufacturer specifications. Always consult the battery’s documentation for precise information regarding its capacity and CCA ratings.

For an accurate assessment of capacity and CCA dependencies, it’s essential to refer to the battery’s documentation. These values should be viewed as rough guidelines and may vary depending on specific battery models and manufacturers.

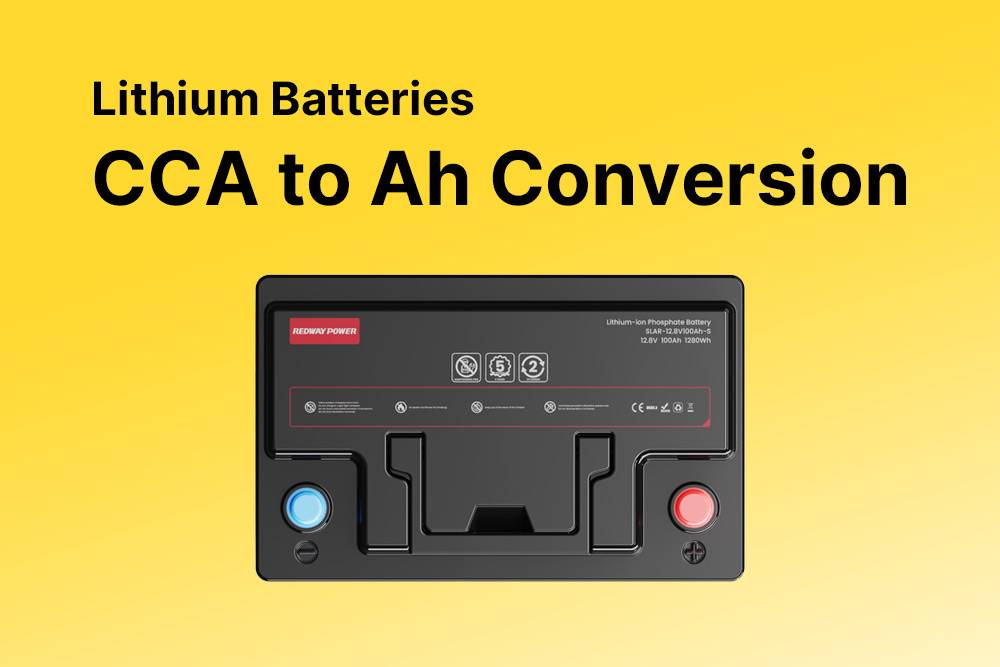

Lithium Batteries CCA to Ah Conversion

Deep Cycle Lithium Iron Phosphate (LiFePO4) batteries in automotive sectors employ Battery Management Systems (BMSs) that disconnect in low temperatures. These batteries have limited currents, with continuous discharge rates at 1C and surge currents at 2-3C for brief periods. Understanding their characteristics aids in optimizing performance

In the automotive and light industrial sectors, most lithium batteries are Deep Cycle Lithium Iron Phosphate (LiFePO4) batteries equipped with Battery Management Systems (BMSs). These systems disconnect the battery in low-temperature conditions, often starting at 32°F (0°C) or even as high as 14°F (-10°C).

Typically, lithium batteries have limited currents, with continuous discharge rates capped at 1C and short-term surge currents reaching 2-3C for brief durations. For instance, a standard LiFePO4 12V 100Ah battery may sustain a maximum continuous current of 100 Amps and surge currents of up to 200Ah for 2-5 seconds.

Therefore, discussing the true Cold Cranking Amps (CCA) value for such batteries becomes irrelevant.

However, some starting lithium batteries may have “CCA” values provided by manufacturers, which are actually equivalent to “MCA” (given for 0°C) or even “PHCA” (given for 25°C), but still labeled as “CCA” values.

Directly converting between CCA and Ah for lithium batteries is impractical due to significant variations. For example, starting lithium batteries may have CCA ratings exceeding 100 Amps, surpassing their nominal capacity given in Amp Hours.

CCA (Amps) = Capacity (Ah) x 100 (commonly used but may not accurately)

For lithium batteries, the formula CCA (Amps) = Capacity (Ah) x 100 is commonly used to estimate the Cold Cranking Amps (CCA) rating. However, it’s important to note that this calculation may not accurately represent the true CCA capability of lithium batteries, as their performance characteristics differ significantly from traditional lead-acid batteries. Additionally, some lithium batteries may not have a true CCA rating due to their design and chemistry, so this formula should be used cautiously and interpreted with consideration for the specific battery model and manufacturer specifications.

These batteries provide substantial weight savings and enhance engine starting and cranking performance. However, they often come at a higher cost compared to traditional lead-acid batteries.

FAQs

What is Cold Cranking Amps (CCA) and Amp Hours (Ah)?

Cold Cranking Amps (CCA) measures a battery’s ability to deliver a strong current for engine starting, typically at 0°F (-18°C), while Amp Hours (Ah) indicates the battery’s capacity to supply a specific current over time, usually 20 hours.

Why is converting CCA to Ah not straightforward?

Converting CCA to Ah is not straightforward because CCA and Ah represent different aspects of battery performance: CCA measures starting power in short bursts, while Ah measures overall capacity over a longer period.

Is there a direct conversion formula between CCA and Ah?

No, there is no direct conversion formula between CCA and Ah due to their fundamentally different measurement contexts and purposes.

How can I estimate Ah from CCA?

While there is no exact conversion, a rough estimation can be made by dividing the CCA value by a constant factor, typically between 15 and 20, to obtain an approximate Ah value.

Why is it important to consider battery chemistry and condition when converting CCA to Ah?

Battery chemistry and condition significantly influence the relationship between CCA and Ah, as different battery types and conditions affect their performance characteristics and efficiency.

Should I rely solely on CCA or Ah ratings when selecting a battery?

It’s essential to consider both CCA and Ah ratings when selecting a battery, as they provide complementary information about a battery’s performance capabilities, particularly in different operating conditions and applications.