Blog

What You Need to Know About Lithium Polymer Batteries

Lithium polymer (LiPo) batteries use a unique polymer electrolyte that replaces the liquid electrolyte found in traditional lithium-ion batteries, delivering lightweight, flexible, and high-energy solutions ideal for modern electronics. Their design offers higher energy density, customizable shapes, and improved safety features, making LiPo batteries essential in applications ranging from mobile devices to electric vehicles.

What is a lithium polymer battery and how does it work?

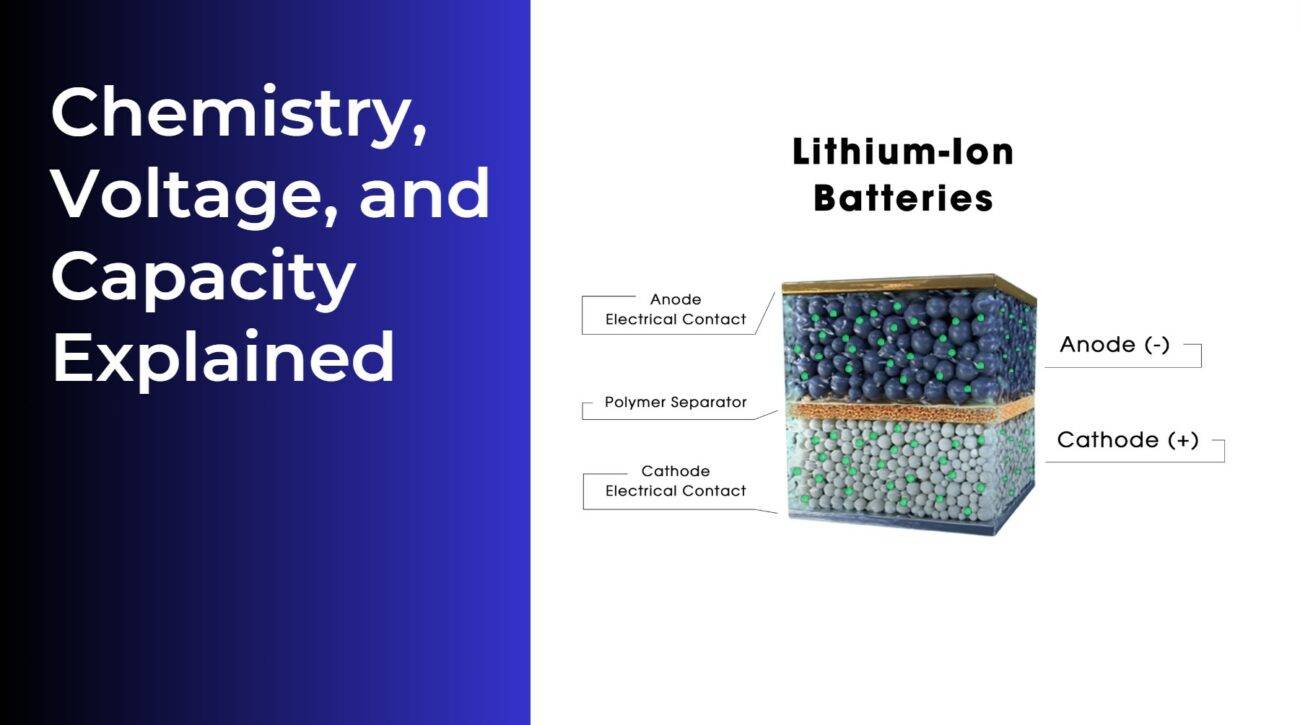

A lithium polymer battery is a rechargeable battery that uses a solid or gel-like polymer electrolyte instead of a liquid electrolyte. This polymer facilitates the movement of lithium ions between the positive cathode and negative anode during charge and discharge cycles. The solid polymer electrolyte improves mechanical stability and allows batteries to be made thinner and lighter, contributing to flexible battery shapes without compromising performance. The basic structure includes the cathode, anode, polymer electrolyte, and separator layers working together to produce electrical energy through lithium-ion intercalation and de-intercalation.

How does lithium polymer chemistry differ from traditional lithium-ion batteries?

Unlike conventional lithium-ion batteries that use liquid electrolytes soaked in porous separators, lithium polymer batteries employ solid or gel polymer electrolytes such as polyethylene oxide (PEO), polyacrylonitrile (PAN), or polyvinylidene fluoride (PVdF). This change enhances safety by reducing flammability risks and mechanical vulnerabilities. Also, polymer electrolytes provide better resistance to vibration, compression, and shock compared to liquid electrolytes, thus improving battery durability and longevity. The polymer structure allows electrodes to expand and contract during charge cycles more flexibly, reducing internal stress.

What are the advantages and benefits of lithium polymer batteries?

Lithium polymer batteries offer several significant advantages:

- Lightweight and flexible form factors enable use in slim or irregularly shaped devices.

- Higher energy density compared to many lithium-ion alternatives, delivering longer run times.

- Improved safety due to less leakage risk and reduced flammability.

- Excellent thermal stability with better tolerance to temperature variation.

- Lower self-discharge rates, aiding longer shelf life.

- Design adaptability supporting innovations in wearable tech, drones, and electric vehicles.

Chart: Comparison of LiPo vs Li-ion Battery Benefits

| Feature | Lithium Polymer (LiPo) | Traditional Lithium-ion |

|---|---|---|

| Electrolyte Type | Solid/Gel Polymer | Liquid Organic Solvent |

| Flexibility | High | Low |

| Weight | Lower | Higher |

| Energy Density | Higher (approx. 10%) | Standard |

| Safety | Enhanced | Moderate |

| Design Shapes | Customizable | Fixed cylindrical/prismatic |

What safety features make lithium polymer batteries reliable?

LiPo batteries integrate inherent safety features such as non-flammable polymer electrolytes and built-in polymer separators that reduce short-circuit risks. Some designs incorporate shutdown layers within the polymer matrix that block current flow if the battery overheats, preventing thermal runaway. Furthermore, advances in battery management systems (BMS) monitor voltage, temperature, and current, enhancing operational safety. Despite these improvements, safe handling, correct charging protocols, and avoiding physical damage remain paramount to preventing hazards.

How are lithium polymer batteries applied across various industries?

Due to their lightweight and adaptable design, lithium polymer batteries are widely used in:

- Consumer electronics like smartphones, tablets, and laptops.

- Remote-controlled drones and model aircraft for high power-to-weight ratio.

- Electric vehicles and e-bikes benefiting from flexibility and energy density.

- Wearable technology requiring thin, pliable batteries.

- Portable power banks and solar energy storage solutions.

- Medical devices needing compact, reliable power sources.

Redway Power’s OEM expertise supports lithium polymer battery production for many such applications, delivering customized solutions to meet industry-specific needs.

How should lithium polymer batteries be charged, maintained, and stored?

Charging LiPo batteries requires specialized chargers adhering to precise voltage and current limits to prevent overcharging. Balanced charging ensures each cell maintains equal voltage, critical for battery health. Proper maintenance involves avoiding deep discharges, storing batteries at 40-60% capacity in cool environments, and protecting them from physical damage or moisture. Routine capacity checks and adherence to manufacturer instructions extend battery lifespan and maintain performance consistency.

What limitations and challenges do lithium polymer batteries face?

Despite advantages, LiPo batteries have challenges including:

- Higher production costs relative to lithium-ion alternatives.

- Limited cycle life compared to some lithium-ion chemistries.

- Sensitivity to overcharging or deep discharge damaging cells.

- Risk of swelling or puncture causing safety hazards.

- Need for robust battery management and protection circuits.

Continuous research and manufacturing improvements, including those pursued by Redway Power, aim to mitigate these limitations through material innovation and quality control.

How does polymer electrolyte enhance battery flexibility and design?

The polymer electrolyte’s semi-solid or gel form allows LiPo batteries to be manufactured in various shapes and sizes beyond rigid cylinders or prisms. This flexibility facilitates integration into slim, curved, or customized device housings without sacrificing energy capacity. Additionally, the mechanical robustness of polymer electrolytes offers resistance to vibration and shock, allowing safer operation in dynamic environments such as electric vehicles and drones.

What manufacturing standards and technologies ensure high-quality lithium polymer batteries?

High-quality LiPo battery production involves stringent ISO certifications and advanced manufacturing execution systems (MES) to monitor every process step, from material control to assembly. Quality control includes electrolyte formulation, electrode coating, cell assembly precision, and leakage testing. Redway Power, accredited with ISO 9001:2015, employs MES technology ensuring consistent performance, safety, and reliability across its lithium polymer battery lines serving diverse OEM sectors.

How does Redway Power’s MES system optimize lithium polymer battery production?

Redway Power utilizes Manufacturing Execution System (MES) technology to streamline lithium polymer battery production with real-time data tracking, process automation, and quality assurance. MES enables precise control over raw materials, assembly conditions, and device testing, reducing defects and improving throughput. This laser-focused manufacturing precision helps Redway Power deliver high-performance lithium polymer batteries that meet rigorous global standards for safer, longer-lasting power solutions.

Redway Power Expert Views

“Lithium polymer battery technology represents a sophisticated confluence of chemistry, materials science, and precision engineering,” explains a Redway Power expert. “Our investment in MES-driven production elevates consistency and quality, positioning us to meet the evolving demands for safer, lighter, and more adaptable batteries. By harnessing polymer electrolyte innovations, we enable a myriad of industries to power next-generation devices with confidence and efficiency.”

Conclusion

Lithium polymer batteries embody a transformative evolution in rechargeable energy storage, replacing liquid electrolytes with advanced polymer materials to offer lightweight, flexible, and safer batteries. While presenting unique benefits in energy density and design adaptability, these batteries require careful handling, specialized charging, and adherence to high manufacturing standards exemplified by Redway Power. Understanding their chemistry, applications, and operational requirements empowers users and manufacturers alike to optimize performance and innovation in energy-dependent technologies.

FAQs

What makes lithium polymer batteries different from lithium-ion batteries?

Lithium polymer batteries use a solid or gel polymer electrolyte, unlike lithium-ion batteries that use liquid electrolytes, enabling flexible shapes and improved safety.

Are lithium polymer batteries safer than traditional lithium-ion?

Yes, polymer electrolytes reduce leakage and flammability risks, and some designs include shutdown features that enhance safety.

Can lithium polymer batteries be used in electric vehicles?

Yes, their high energy density and flexible design make them suitable for electric vehicles, drones, and portable electronics.

How should I store lithium polymer batteries?

Store them in a cool, dry place at around 40-60% charge, avoiding exposure to extreme temperatures or physical damage.

How does Redway Power ensure the quality of its lithium polymer batteries?

Through ISO 9001:2015 certification and advanced MES manufacturing systems, Redway Power maintains rigorous quality and consistency in its battery production.