Shunts are vital components within electrical systems, playing a crucial role in various applications. Understanding their function, applications, and importance is essential for effective system monitoring and maintenance.

Understanding Shunts in Electrical Systems

A shunt in an electrical system serves as a precision current-sensing device. Its primary function is to divert a known fraction of the current flowing through a circuit away from the main path. By doing so, it enables accurate measurement of electric current without interrupting the circuit’s operation. Shunts are typically constructed from low-resistance materials, ensuring minimal voltage drop across them.

Applications of Shunts

Electrical shunts find widespread use across various industries and applications, serving critical roles in power distribution systems, electrical measurement setups, as well as automotive and marine technologies. Shunts find widespread use in diverse electrical systems and equipment. One common application is in ammeters, where shunts enable the measurement of high electrical currents. Additionally, they are integral components of battery monitoring systems, allowing for accurate measurement and monitoring of battery charge/discharge currents. In renewable energy systems, such as solar power installations, shunts facilitate precise monitoring of energy flows and battery status.

- Power Distribution Systems: In power distribution systems, electrical shunts are often used for current monitoring and control. They provide a precise measurement of current flowing through a circuit, enabling operators to manage and balance loads effectively. This helps prevent overloading, ensures safety, and optimizes the efficiency of the distribution network.

- Electrical Measurement Systems: Electrical shunts serve as essential components in various measurement setups, such as ammeters and wattmeters. By accurately measuring current or voltage, shunts enable the monitoring and analysis of electrical parameters in diverse settings, ranging from laboratory experiments to industrial processes.

- Automotive Applications: In automotive systems, electrical shunts play crucial roles in measuring and managing current flow, particularly in battery management systems (BMS) and charging circuits. They help monitor the charging and discharging of batteries, ensuring optimal performance and extending battery life. Shunts are also used in automotive instrumentation for measuring parameters like fuel efficiency and engine performance.

- Marine Applications: Electrical shunts are vital components in marine electrical systems, where they monitor and control current flow in various onboard circuits. They facilitate accurate measurement of electrical parameters in marine propulsion systems, navigation equipment, and power generation systems. Shunts also support the safe and efficient operation of electrical equipment on ships and boats.

Overall, electrical shunts are versatile devices with applications spanning multiple industries, where their precise current measurement capabilities contribute to efficient operation, performance optimization, and safety across various electrical systems and equipment.

Shunting Wires Defined

Shunting wires involves the use of a shunt to divert a known portion of current in a circuit. This process allows for accurate measurement of current flow without affecting the circuit’s overall operation. Shunting wires is particularly useful in situations where precise current measurement is required, such as in battery management systems or power distribution networks.

Importance of Shunt-Based Current Measurement

Measuring current via a shunt is crucial for several reasons. Firstly, it enables accurate monitoring of electrical systems, ensuring optimal performance and preventing overloading or damage. Additionally, shunt-based current measurement provides valuable data for diagnostics and troubleshooting, allowing for early detection of issues such as excessive current draw or battery degradation.

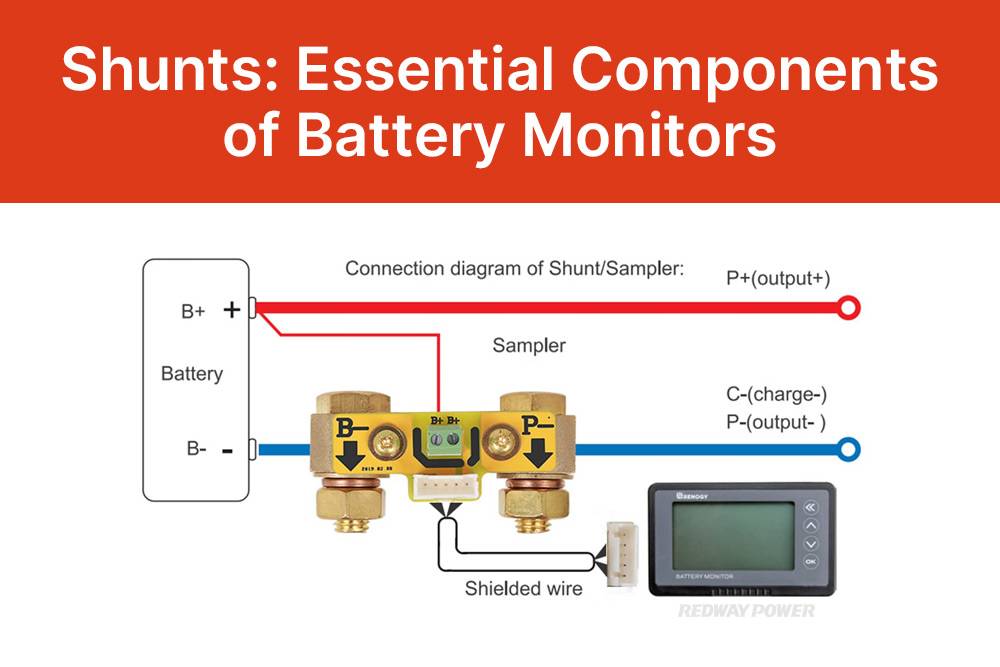

Communication Between Shunt and Battery Monitor

In battery monitoring systems, communication between the shunt and the battery monitor is essential for accurate data collection and analysis. Typically, the shunt is connected to the battery monitor via dedicated wiring or communication protocols such as CAN bus. The battery monitor then processes the current measurements from the shunt, providing real-time data on battery status, charge/discharge rates, and overall system health.

Mounting Locations for Electrical Shunts

Determining the optimal mounting location for electrical shunts depends on various factors, including system layout, wiring configuration, and space constraints. Ideally, shunts should be installed close to the point of current measurement to minimize voltage drop and ensure accurate readings. Common mounting locations include near battery terminals, in-line with high-current cables, or within dedicated shunt compartments in electrical enclosures.

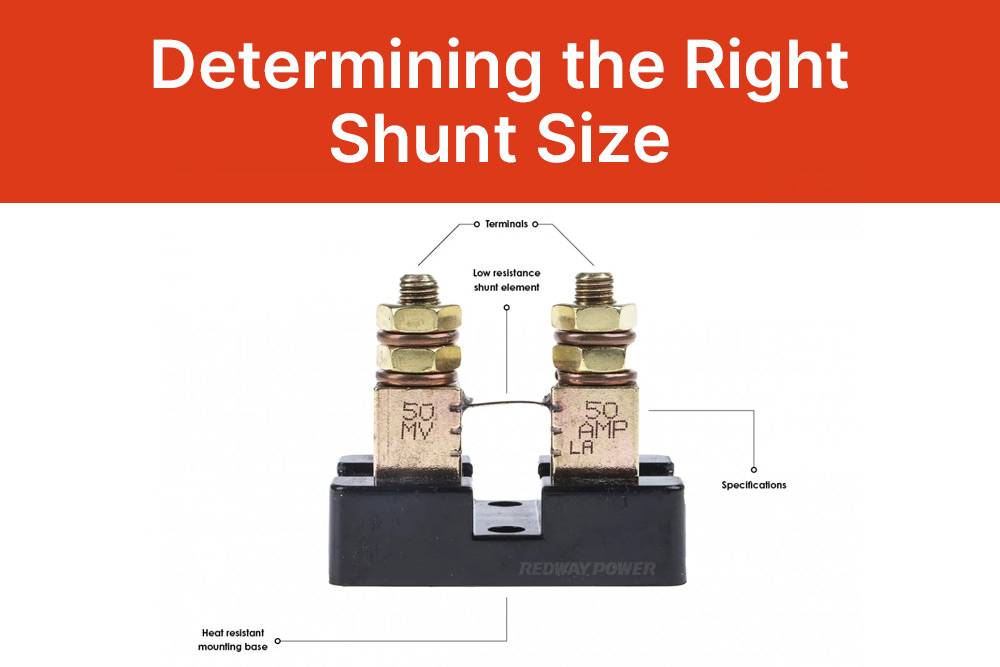

Determining the Right Shunt Size

Selecting the correct size of an electrical shunt is critical for accurate current measurement and system performance. Shunt size is determined based on the maximum expected current flow in the circuit, ensuring that the shunt can handle the required load without exceeding its capacity. Factors such as shunt resistance and thermal dissipation capabilities also influence size selection, with larger shunts typically capable of handling higher currents.

Temperature Considerations for Shunts

During operation, shunts may generate heat due to the flow of electrical current through them. While some heat generation is normal, excessive temperatures can affect shunt accuracy and reliability. Proper thermal management, such as adequate ventilation and heat sinking, is essential to prevent overheating and ensure consistent performance. Additionally, selecting shunts with appropriate thermal specifications for the intended application can help mitigate temperature-related issues.

Shunts: Essential Components of Battery Monitors

In battery monitoring systems, shunts serve as the heart of the monitoring process, providing crucial data on battery performance and health. By accurately measuring current flow in and out of batteries, shunts enable precise monitoring of battery state of charge, charge/discharge rates, and overall system efficiency. Battery monitors rely on shunt measurements to provide real-time data and alerts, helping users optimize battery usage and prolong battery life.

In conclusion, shunts play a central role in electrical systems, enabling accurate current measurement and monitoring across various applications. Understanding their function, applications, and proper usage is essential for maintaining system reliability and performance, particularly in critical applications such as battery monitoring and renewable energy systems. By implementing appropriate shunt-based monitoring solutions, users can ensure optimal system performance and reliability while minimizing risks associated with inaccurate current measurement.