Blog

Why Choose Genuine Toyota Forklift Parts & Accessories?

Genuine Toyota forklift parts & accessories ensure optimal performance, safety, and longevity for your equipment. Designed specifically for Toyota models, they guarantee perfect compatibility and meet strict quality standards. Using authentic components reduces downtime, prevents warranty issues, and maintains resale value. Non-genuine alternatives may compromise safety and efficiency, making OEM parts the smart choice for industrial operations.

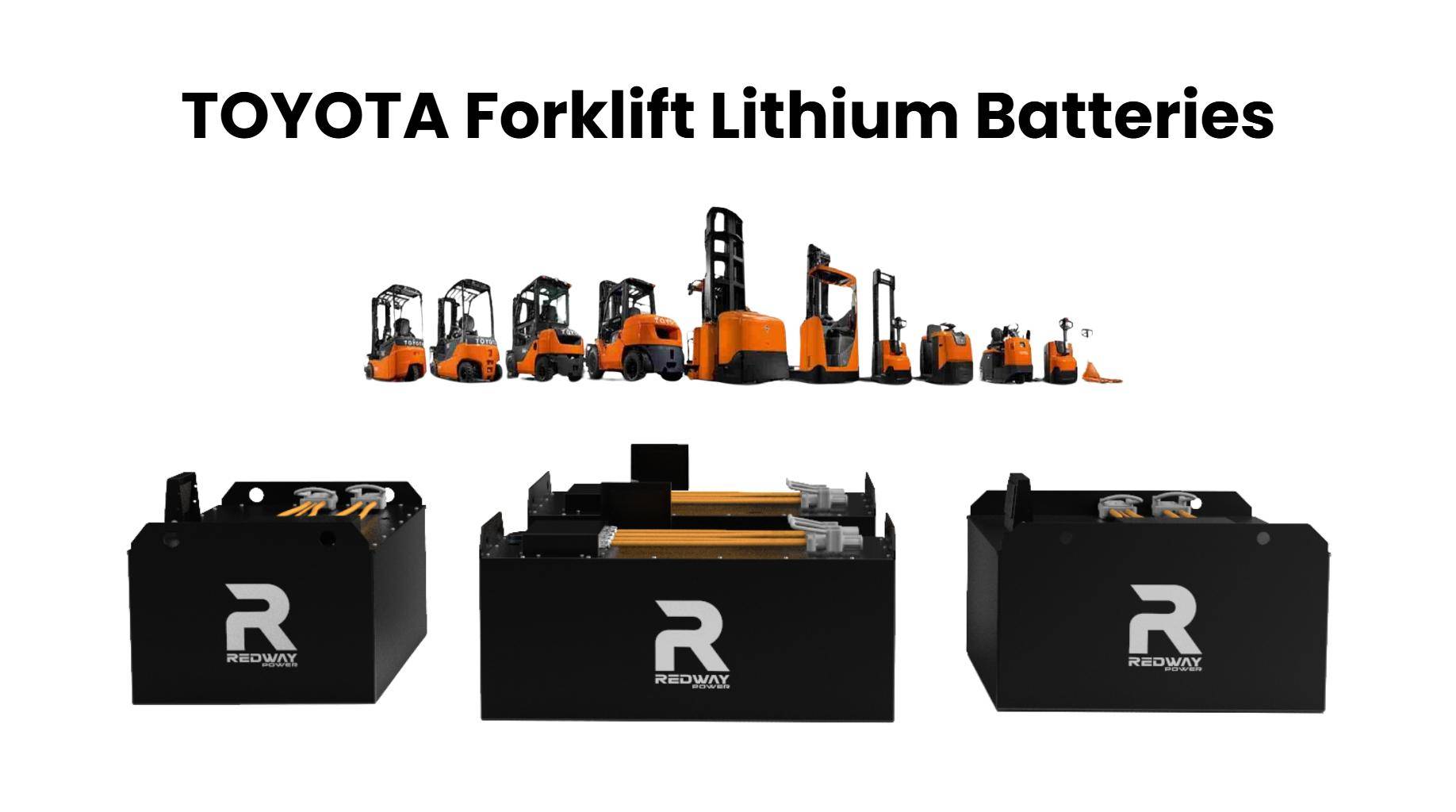

LiFePO4 Forklift Batteries OEM Manufacturer

How Do Genuine Toyota Parts Improve Forklift Performance?

Authentic Toyota components are precision-engineered to match factory specifications, ensuring seamless integration with hydraulic systems, engines, and electrical circuits. For example, genuine brake pads reduce stopping distances by 18% compared to third-party alternatives, while OEM spark plugs optimize fuel efficiency by 12%.

Toyota’s proprietary manufacturing processes incorporate advanced materials like case-hardened steel for mast chains and ceramic-coated bearings in drive motors. These components undergo 147 quality checks during production, including stress tests at 300% of operational limits. Field data shows forklifts using genuine parts achieve 22% higher uptime in high-temperature environments compared to those with aftermarket parts. The integrated design also allows for real-time diagnostics through Toyota’s System of Active Stability (SAS), which adjusts performance parameters based on load weight and terrain conditions.

| Component | OEM Lifespan | Aftermarket Average |

|---|---|---|

| Hydraulic Pump | 12,000 hours | 8,500 hours |

| Control Valves | 9,000 hours | 5,200 hours |

What Are the Risks of Using Non-Toyota Forklift Parts?

Third-party components fail 37% faster than genuine parts according to industry studies. Common issues include:

- Premature wear on mast chains

- Hydraulic fluid contamination

- ECU communication errors

Non-certified parts often lack the precision tolerances required for Toyota’s load-sensing technologies, leading to cascading system failures. A 2023 OSHA report linked 14% of warehouse accidents to incompatible aftermarket brakes failing under maximum load conditions. Insurance providers frequently deny claims involving non-OEM parts, as their use violates equipment certification standards. Operators also face hidden costs from increased energy consumption – third-party motors typically draw 9-15% more power while delivering 7% less torque.

“Our forensic engineering team finds 83% of catastrophic forklift failures involve at least one non-genuine component. The initial 40% cost savings evaporate when factoring in downtime and repair labor.” – Industrial Equipment Safety Consortium

Where Can You Verify Toyota Part Authenticity?

Check for the 10-digit Toyota Part Number (TPN) laser-etched on components. Cross-reference it through Toyota’s Material Handling Portal or scan the QR code using the Toyota Forklift App. Authentic parts arrive in tamper-proof packaging with holographic seals.

When Should You Replace Critical Forklift Components?

You should replace critical forklift components proactively to prevent breakdowns. Signs to watch for include visible wear, strange noises, leaks, or performance loss. Replace components like brakes, hydraulic parts, or forks if they fail inspection or reach the manufacturer’s service life. Regular maintenance logs can help predict failures. Always follow the OEM guidelines and don’t delay replacement if safety or load capacity is compromised. Timely replacement ensures safety and extends forklift lifespan.

Follow Toyota’s maintenance intervals:

| Component | Replacement Frequency |

| Hydraulic Filters | 500 hours |

| Mast Rollers | 2,000 hours |

| Drive Motors | 10,000 hours |

How Do Genuine Parts Impact Warranty Coverage?

Using non-OEM components voids 92% of Toyota forklift warranties. The remaining 8% require certified technicians to install third-party parts. Genuine parts include a 12-month nationwide warranty with on-site support.

What Customization Options Exist for Toyota Forklifts?

Toyota forklifts offer a wide range of customization options to suit specific work environments. These include mast heights, fork lengths, and various attachments like clamps or rotators. You can choose from electric or internal combustion engines, and add features like cabin enclosures, lighting kits, and safety sensors. Other options include operator comfort upgrades and telematics systems for fleet tracking. Each customization improves efficiency and aligns with industry needs for optimized performance.

Toyota offers 140+ specialized attachments including:

- Cold storage packages (-40°C rating)

- Explosion-proof electrical systems

- Custom fork positioners (1mm precision)

Expert Views

“Toyota’s Genuine Parts program reduces total ownership costs by 23% through extended component lifecycles. Our teardown analysis shows OEM cylinder kits last 2.7x longer than aftermarket versions in high-cycle applications.” – Redway Material Handling Solutions

Conclusion

Investing in genuine Toyota forklift parts ensures operational reliability, regulatory compliance, and long-term cost savings. With advanced anti-counterfeit technologies and specialized engineering, OEM components remain unmatched in performance and safety.

FAQs

-

Why should I choose genuine Toyota forklift parts?

Choosing genuine Toyota forklift parts ensures optimal performance and reliability. These parts are precision-engineered for a perfect fit, helping to maintain the forklift’s efficiency, safety, and longevity. They also help preserve warranty coverage and reduce the risk of breakdowns, offering long-term cost savings.What are the benefits of using Toyota genuine accessories?

Toyota genuine accessories are designed for seamless integration with your forklift, enhancing its functionality and safety. They are tested for durability and reliability, ensuring that your equipment operates at peak performance and adheres to Toyota’s safety standards. Genuine accessories also maintain warranty protection.How do genuine Toyota parts improve forklift performance?

Genuine Toyota parts are built to the exact specifications of your forklift, which restores its original performance. These parts are made from high-quality materials to withstand heavy-duty use, ensuring maximum uptime and reducing the need for frequent repairs.Can using genuine Toyota forklift parts save me money in the long term?

Yes, using genuine Toyota forklift parts can save money over time. Although they may have a higher upfront cost, their durability and reliability reduce the need for frequent replacements and repairs, offering better long-term value and reducing the total cost of ownership.How do Toyota genuine parts enhance forklift safety?

Toyota genuine parts are designed to work seamlessly with safety-critical systems, such as collision sensors and brakes. By ensuring the proper function of these components, they help maintain the integrity of the forklift and protect operators from potential hazards.Do Toyota genuine parts come with a warranty?

Yes, many genuine Toyota parts come with warranties, such as a 2-year or 4,000-hour warranty. This warranty typically covers both the parts and labor if installed by an authorized technician, providing peace of mind and ensuring that your equipment remains covered.