Blog

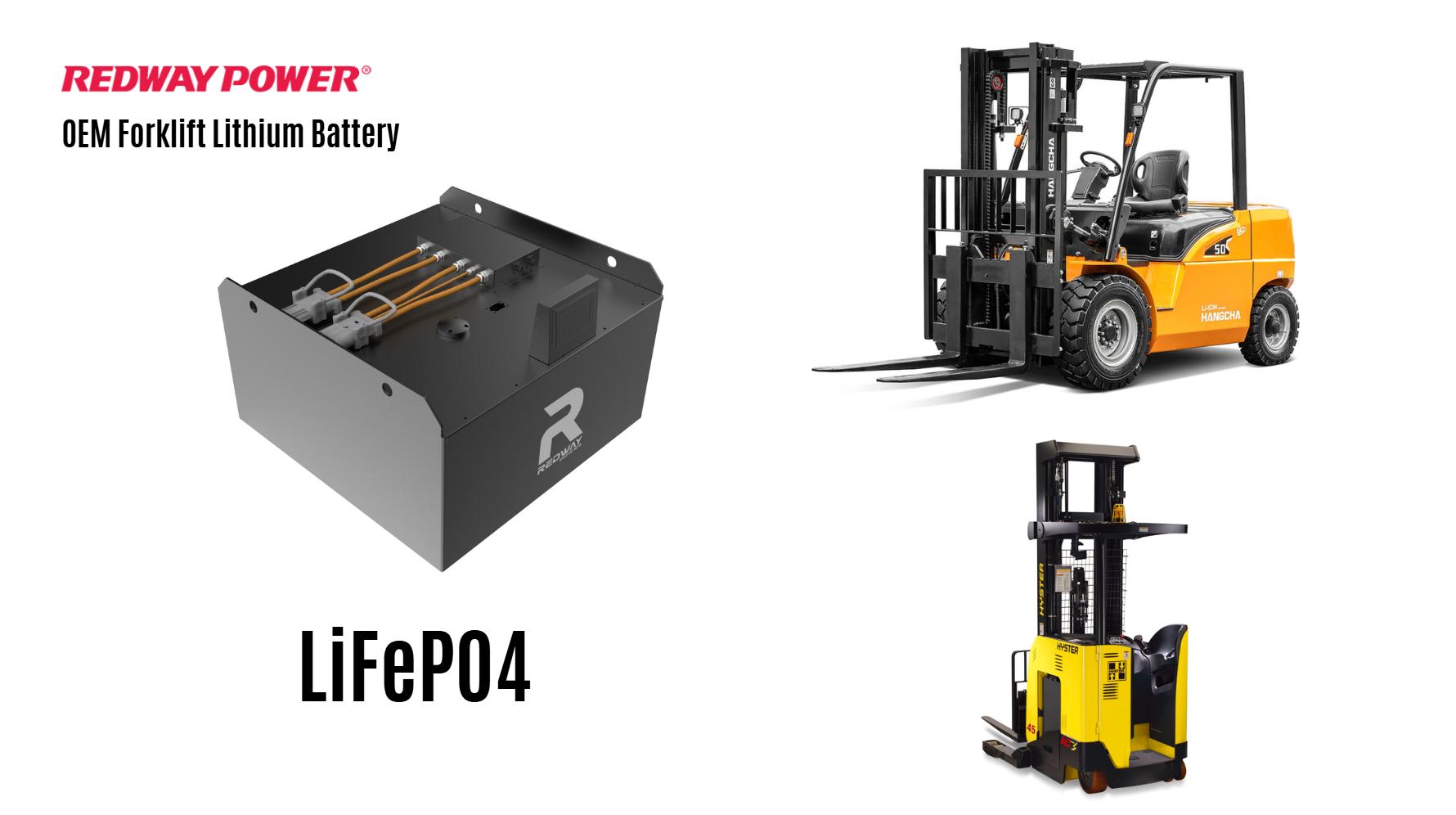

Why Choose LiFePO4 Batteries for Heavy-Duty Forklifts?

LiFePO4 (lithium iron phosphate) batteries provide superior energy density, longer lifespans (3,000–5,000 cycles), and faster charging compared to traditional lead-acid batteries. They thrive in heavy-duty forklift applications due to their ability to withstand frequent deep discharges, reduced maintenance needs, and stable performance in extreme temperatures. These features minimize downtime and operational costs in industrial settings.

What Makes LiFePO4 Batteries Ideal for Industrial Forklifts?

LiFePO4 batteries excel in industrial environments due to their robust thermal stability, high energy efficiency (95% vs. 80% for lead-acid), and lightweight design. Their modular architecture allows seamless integration into forklift battery compartments, while built-in Battery Management Systems (BMS) prevent overcharging, overheating, and voltage fluctuations. For example, Redway Power’s 48V LiFePO4 packs deliver 210Ah capacity with a 10-year lifespan under daily use.

Industrial facilities benefit from the battery’s ability to maintain consistent voltage output throughout discharge cycles. Unlike lead-acid models that experience voltage sag under heavy loads, LiFePO4 units ensure stable power delivery even at 80% depth of discharge. This translates to predictable performance during peak shifts. The absence of liquid electrolytes also eliminates spill risks in food processing or pharmaceutical warehouses. Modern designs incorporate shock-resistant casings and IP54-rated enclosures to withstand impacts from loading docks and exposure to industrial debris.

| Feature | LiFePO4 | Lead-Acid |

|---|---|---|

| Energy Efficiency | 95% | 50-60% |

| Peak Power Output | 5C Continuous | 1.5C Maximum |

| Temperature Tolerance | -20°C to 60°C | 0°C to 40°C |

How Do LiFePO4 Batteries Compare to Lead-Acid in Forklift Performance?

- Cycle Life: LiFePO4 lasts 3–5x longer (3,000–5,000 cycles vs. 1,000–1,500 for lead-acid).

- Charging Speed: 1–2 hours for lithium vs. 8–10 hours for lead-acid.

- Energy Efficiency: 95% usable capacity vs. 50% for lead-acid.

- Weight: LiFePO4 batteries are 30–50% lighter, reducing forklift strain.

The operational advantages become particularly evident in multi-shift operations. A lithium-powered forklift can utilize opportunity charging during 30-minute breaks to maintain 90%+ charge levels throughout the day. Lead-acid batteries require full recharge cycles to avoid sulfation damage, forcing operators to maintain spare batteries. In cold storage applications, LiFePO4 maintains 85% of its rated capacity at -15°C, while lead-acid efficiency plummets to 40%. This reliability allows warehouses to reduce fleet sizes by 15-20% while maintaining throughput targets.

Also check:

What Are the Cost Benefits of Switching to LiFePO4 Forklift Batteries?

Switching to LiFePO4 forklift batteries offers significant long-term savings despite higher upfront costs. They last 3-5 times longer than lead-acid batteries, require zero maintenance, and charge 3 times faster, reducing downtime. Energy efficiency improvements cut electricity bills by up to 40%, and fewer replacements lower total ownership costs. Businesses benefit from increased productivity and lower labor costs, achieving ROI typically within 2-3 years, making LiFePO4 batteries a cost-effective investment.

While LiFePO4 batteries have 2–3x higher upfront costs ($4,000–$8,000 vs. $2,000–$5,000 for lead-acid), they reduce long-term expenses:

- No watering, equalizing, or acid disposal costs ($200–$500/year saved).

- 50–70% lower energy consumption due to efficient charging.

- Extended lifespan cuts replacement frequency by 60%.

A 2023 study by Industrial Battery Journal showed ROI within 18–30 months for warehouses operating 20+ forklifts.

How to Maintain LiFePO4 Batteries for Optimal Forklift Performance?

Maintain LiFePO4 batteries by ensuring proper charging with compatible chargers and avoiding deep discharges. Keep terminals clean and store batteries in cool, dry environments to prevent thermal stress. Use built-in Battery Management Systems (BMS) to monitor voltage, temperature, and state of charge. Regular inspections and avoiding overcharging or overheating extend battery life and maintain consistent forklift performance. Unlike lead-acid, LiFePO4 batteries require minimal physical maintenance.

LiFePO4 requires minimal maintenance:

- Avoid deep discharges below 20% capacity.

- Store at 50% charge if unused for >30 days.

- Use compatible chargers (CC/CV profiles).

- Clean terminals quarterly with non-conductive brushes.

BMS auto-balancing ensures cell stability, eliminating manual voltage checks.

Can LiFePO4 Batteries Withstand Extreme Warehouse Conditions?

Yes. LiFePO4 operates in -20°C to 60°C (-4°F to 140°F) ranges, outperforming lead-acid’s 0°C–40°C limits. Their ceramic-coated cathodes prevent thermal runaway, making them safer in humid or dusty environments. For example, Toyota’s lithium-powered 8FGCU25 forklifts maintain 85% capacity after 5 years in -15°C cold storage facilities.

Expert Views

“LiFePO4 is revolutionizing material handling. Unlike lead-acid, these batteries support opportunity charging during breaks, boosting productivity by 15–20%. At Redway, we’ve seen clients reduce energy costs by $12,000 annually per 50 forklifts while meeting sustainability targets.”

Conclusion

LiFePO4 batteries offer unmatched durability, efficiency, and cost savings for heavy-duty forklifts. With advancements in fast-charging infrastructure and declining lithium prices (18% drop since 2021), industries are rapidly adopting this technology to streamline operations and meet ESG goals.

FAQs

- How long do LiFePO4 forklift batteries last?

- 8–10 years or 3,000–5,000 cycles, 3x longer than lead-acid.

- Can I retrofit LiFePO4 into older forklift models?

- Yes, 90% of Class I–III forklifts support lithium upgrades with adapter kits.

- Are LiFePO4 batteries UL-certified for industrial use?

- Most premium brands like Redway and RELiON meet UL 2580, IEC 62619, and UN38.3 standards.