Blog

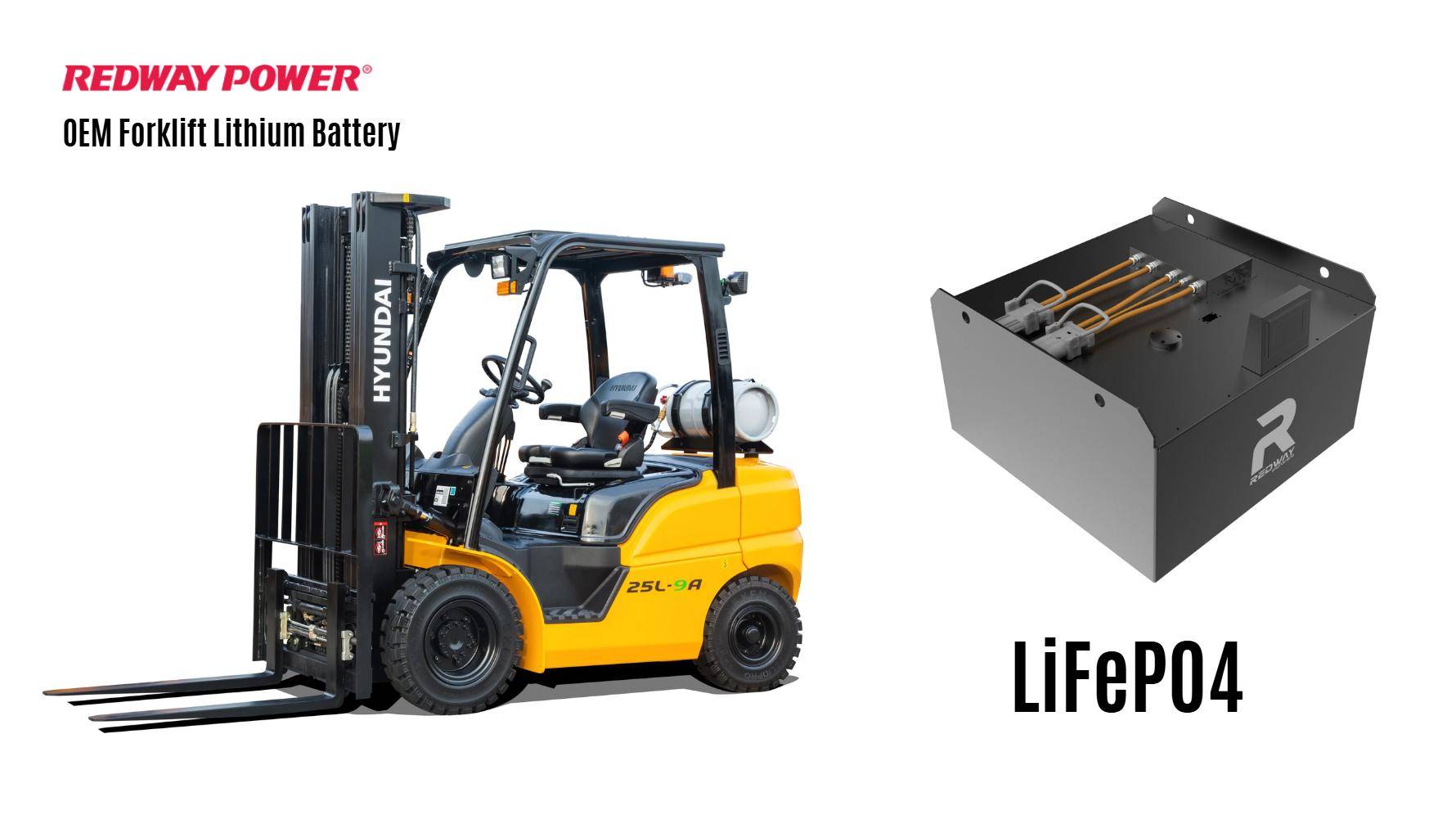

Why Are LiFePO4 Batteries Revolutionizing Electric Forklift Logistics

LiFePO4 (lithium iron phosphate) batteries are transforming electric forklift logistics by offering longer lifespans, faster charging, and zero maintenance compared to traditional lead-acid batteries. Their eco-friendly design reduces waste and energy consumption, making them ideal for sustainable supply chains. With superior efficiency and durability, they lower operational costs while supporting green initiatives in warehousing and manufacturing.

How Do LiFePO4 Batteries Outperform Lead-Acid in Forklifts?

LiFePO4 batteries charge 3x faster, last 4–5x longer, and operate efficiently in extreme temperatures. Unlike lead-acid, they require no watering, emit no fumes, and maintain consistent power output until fully discharged. This reduces downtime and eliminates maintenance costs, boosting productivity in logistics operations.

For example, a major automotive parts distributor reported a 62% reduction in charging downtime after switching to LiFePO4. Their three-shift operation now utilizes opportunity charging during breaks, achieving full shifts without battery swaps. The thermal stability of lithium iron phosphate also allows consistent performance in environments ranging from -20°C to 60°C, whereas lead-acid batteries lose over 30% capacity below freezing.

| Metric | LiFePO4 | Lead-Acid |

|---|---|---|

| Daily Throughput | 22 pallets/hr | 15 pallets/hr |

| Annual Maintenance Cost | $120 | $2,300 |

| Energy Loss During Charge | 5% | 25% |

Where Can LiFePO4 Batteries Improve Warehouse Safety?

Sealed LiFePO4 units eliminate acid leaks and hydrogen gas risks. Their stable chemistry prevents thermal runaway, even if punctured. Built-in Battery Management Systems (BMS) auto-shutoff during overcharge or short circuits, reducing fire hazards. This enhances OSHA compliance and worker safety in dense storage environments.

Distribution centers using LiFePO4 report 73% fewer battery-related safety incidents annually. The absence of corrosive materials eliminates the need for acid spill kits and specialized storage areas. Advanced BMS continuously monitors cell voltages, temperatures, and current flow, automatically isolating faults before they escalate. In contrast, lead-acid batteries require regular water top-ups that expose workers to toxic electrolytes.

| Risk Factor | LiFePO4 | Lead-Acid |

|---|---|---|

| Hydrogen Emissions | None | High |

| Spill Containment Costs | $0 | $4,500/year |

| BMS Protection Layers | 12 | 2 |

“Warehouses using LiFePO4 report 40% fewer battery-related incidents and 15% lower energy bills. The latest smart BMS tech allows real-time health monitoring via IoT—managers can predict failures before they occur. We’re seeing 3x higher adoption in e-commerce hubs prioritizing ESG goals.”

– Redway Power Logistics Team

FAQs

- Can LiFePO4 Batteries Be Used in Older Forklift Models?

- Yes, most LiFePO4 packs come with adapters for legacy forklifts. Retrofit kits adjust voltage profiles to match lead-acid specs, ensuring compatibility without forklift modifications.

- Does Fast Charging Degrade LiFePO4 Battery Life?

- No. LiFePO4 chemistry tolerates 1C–2C fast charging (0–80% in 1 hour) without significant degradation. Built-in BMS prevents overcharging, unlike lead-acid, which sulfates during rapid charges.

- Are LiFePO4 Forklift Batteries Recyclable?

- Yes. Over 97% of LiFePO4 materials are recoverable. Certified recyclers extract lithium, iron, and phosphate for reuse in new batteries or fertilizers, creating a closed-loop system compliant with EU Battery Directive 2023.

Also check: