Blog

What Are the Best Wholesale and OEM Options for Telecom Lithium Batteries?

Telecom lithium batteries offer high energy density, long cycle life, and thermal stability for network infrastructure. Wholesale options provide bulk pricing for telecom operators, while OEM solutions enable custom battery configurations meeting specific voltage/capacity requirements. Leading suppliers include companies like EEMB, EVE Energy, and Panasonic, with certifications like UL/IEC ensuring safety compliance.

What Makes Lithium Batteries Ideal for Telecom Applications?

Lithium-ion batteries outperform lead-acid alternatives in telecom through:

• 60% higher energy density in compact footprints

• 2,000+ deep discharge cycles at 80% DoD

• -20°C to 60°C operational temperature range

• 95% round-trip efficiency vs. 80% for VRLA

• 10-year design life with integrated battery management systems (BMS)

Recent field studies show lithium batteries maintain 92% capacity after 5 years in tower deployments, compared to 63% for AGM alternatives. Their low self-discharge rate (3% monthly) proves critical for backup systems requiring 72+ hour autonomy. Advanced thermal management enables stable operation during power surges common in 5G networks, with built-in cell balancing extending pack longevity by 40% compared to conventional designs.

How Do Wholesale Purchasing Strategies Reduce Telecom Costs?

Bulk procurement of lithium telecom batteries achieves:

• 18-25% volume discounts on 50+ unit orders

• Consolidated logistics with DDP shipping terms

• MOQ flexibility from 100Ah to 10,000Ah capacities

• Vendor-managed inventory programs

• Spare part standardization across tower sites

| Order Size | Price per kWh | Lead Time |

|---|---|---|

| 50-200 units | $280 | 45 days |

| 201-500 units | $265 | 60 days |

| 500+ units | $242 | 90 days |

Operators leveraging frame agreements with tiered pricing report 31% lower TCO over 7-year battery lifecycles. Consolidated shipping reduces customs clearance delays by 65% through single-point documentation. Some vendors offer consignment stock programs where batteries remain supplier-owned until deployment, freeing working capital for network expansion projects.

Which Certifications Are Critical for OEM Telecom Batteries?

Mandatory certifications include:

• UL 1973 (stationary storage)

• IEC 62619 (industrial batteries)

• UN38.3 (transportation)

• CE/RoHS (EU compliance)

• Telcordia GR-3150 (telecom standards)

Third-party testing reports for vibration (IEC 60068-2-64) and thermal runaway prevention are equally crucial for grid-connected deployments.

| Certification | Scope | Testing Body |

|---|---|---|

| IEC 62620 | Cycle life validation | TÜV SÜD |

| ETSI EN 300 019 | Environmental resilience | Intertek |

| ATEX Directive | Explosion protection | UL Solutions |

Manufacturers with ISO 9001/14001 certifications demonstrate consistent quality control across production batches. Regional variations apply – FCC Part 15 compliance is mandatory for US installations to prevent electromagnetic interference with telecom equipment. Third-party verification of IP ratings ensures enclosures meet specified dust/water protection levels across different climate zones.

Know more:

How to Choose the Best Telecom Lithium Battery for Your Needs?

What Are the Best Wholesale and OEM Options for Telecom Lithium Batteries?

What Are the Cost Benefits of Telecom Lithium Batteries?

How to Troubleshoot Telecom Lithium Batteries: Expert Support Guide

What You Need to Know About Telecom Lithium Battery Warranties and Support?

How to Get a Quote or Consultation for Telecom Lithium Batteries?

Can Lithium Batteries Integrate With Existing Telecom Power Systems?

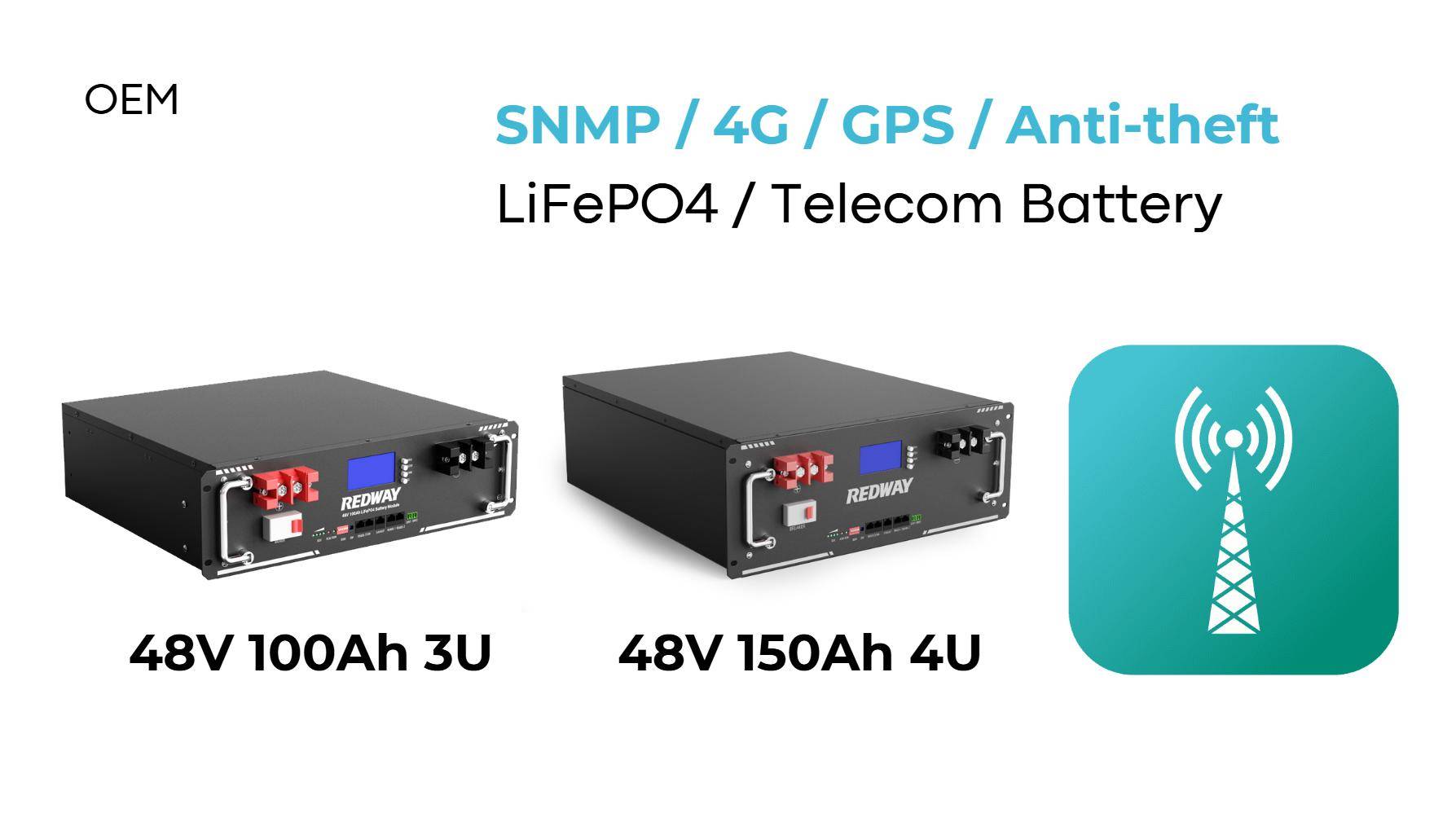

Modern LiFePO4 telecom batteries feature:

• 48VDC nominal voltage compatibility

• RS485/CAN bus communication protocols

• DIN-rail or rack-mount form factors

• Automatic voltage matching (43.2V-58.4V range)

• Hot-swappable designs for parallel redundancy

Retrofit kits with adapter plates and terminal converters enable seamless replacements of legacy NiCd/VRLA systems.

What Customization Options Exist for OEM Telecom Batteries?

Specialized OEM configurations include:

• IP65 enclosures for outdoor macro sites

• Heating pads for -40°C arctic deployments

• Custom BMS firmware with SNMP traps

• Dual-input terminals for hybrid solar/diesel systems

• Shock-absorbent mounts for earthquake zones

• Flame-retardant ABS/polycarbonate composite casings

How Does Cell Chemistry Impact Telecom Battery Performance?

NMC (Nickel Manganese Cobalt) cells provide 200Wh/kg density for space-constrained sites, while LFP (Lithium Iron Phosphate) offers 4,000+ cycles for high-cycling applications. Emerging chemistries like LMFP (Lithium Manganese Iron Phosphate) combine 160Wh/kg density with 3,500-cycle durability at 100% DoD, reducing Levelized Cost of Storage (LCOS) by 22%.

“The telecom sector is transitioning to lithium batteries at 19.3% CAGR, driven by 5G backhaul requirements. Smart BMS with predictive analytics now enable 98.7% system uptime through early failure detection. Our hybrid solutions combine lithium batteries with supercapacitors for 0.3ms load transfer during grid outages.”

– Dr. Chen, Power Systems Director at Huawei Energy

Conclusion

Telecom operators should prioritize OEM partners offering UL/IEC-certified lithium batteries with modular architectures. Wholesale contracts with SLA-backed 10-year performance guarantees ensure optimal TCO. Advanced BMS integration and chemistry-specific deployment strategies will dominate next-gen network power strategies.

FAQs

- What Is the Minimum Order Quantity for Telecom Batteries?

- Standard MOQs start at 20kWh for custom OEM orders and 100kWh for wholesale contracts. Some suppliers offer trial orders of 5-10 units for site validation.

- How Long Do Telecom Lithium Batteries Last?

- Properly maintained LiFePO4 batteries deliver 8-12 years service life in telecom applications, achieving 80% capacity retention after 3,500 cycles at 25°C ambient temperature.

- Are Lithium Batteries Safe for Indoor Telecom Cabinets?

- UL 9540A-compliant systems with thermal runaway containment and gas venting mechanisms meet NFPA 855 safety standards for indoor deployments. Minimum 1m clearance from combustibles is recommended.