Blog

Why Are LiFePO4 Batteries Dominating Material Handling Markets?

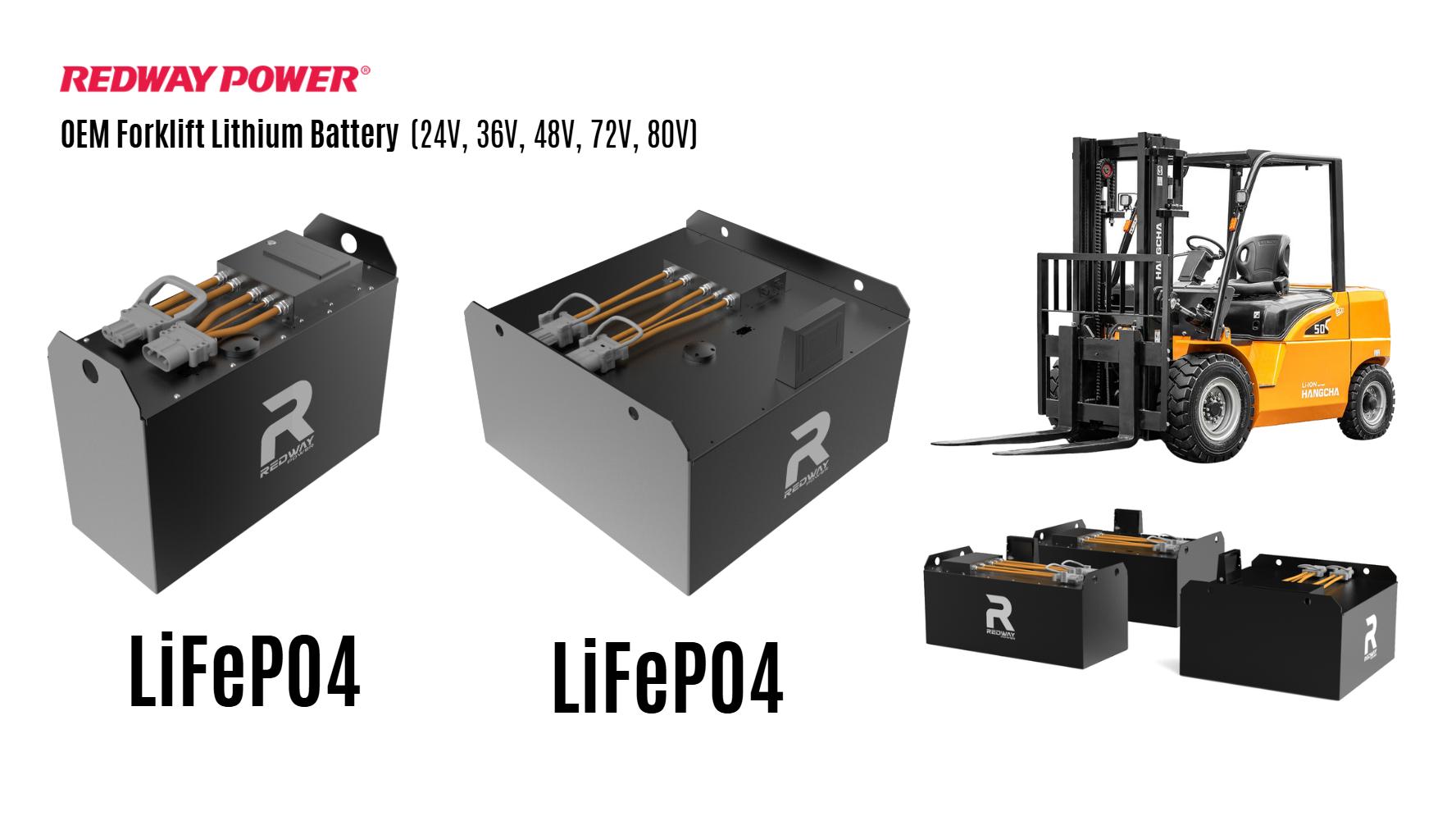

Why are LiFePO4 batteries becoming the top choice in material handling? LiFePO4 (lithium iron phosphate) batteries are dominating material handling due to their long lifespan, fast charging, and high energy density. They outperform lead-acid alternatives by offering lower maintenance, zero emissions, and 3–5x longer cycle life, making them ideal for forklifts, automated guided vehicles (AGVs), and warehouse equipment.

What Makes LiFePO4 Batteries Ideal for Material Handling?

LiFePO4 batteries excel in material handling due to their ability to handle high discharge rates, operate in wide temperature ranges, and maintain consistent voltage. Unlike lead-acid batteries, they don’t require watering or equalization, reducing downtime. Their lightweight design also improves equipment maneuverability and energy efficiency.

How Do LiFePO4 Batteries Compare to Lead-Acid in Forklifts?

LiFePO4 batteries charge 3x faster than lead-acid, enabling opportunity charging during breaks. They last 2,000–5,000 cycles versus 1,000–1,500 for lead-acid, reducing replacement costs. Lead-acid batteries lose capacity in cold environments, while LiFePO4 retains 80% efficiency at -20°C. Additionally, LiFePO4 eliminates hydrogen gas risks and acid spills.

| Feature | LiFePO4 | Lead-Acid |

|---|---|---|

| Charge Time | 1-2 hours | 6-8 hours |

| Cycle Life | 2,000-5,000 | 1,000-1,500 |

| Operating Temp | -30°C to 60°C | 0°C to 40°C |

Recent field studies show LiFePO4-powered forklifts achieve 22% faster lifting speeds due to stable voltage output. Unlike lead-acid models that degrade during partial discharges, lithium batteries maintain full capacity regardless of charge cycles. This allows warehouses to implement “opportunity charging” strategies—topping up batteries during 15-minute breaks without harming longevity. Major manufacturers like Toyota now offer factory-installed LiFePO4 options with integrated telematics for real-time battery health monitoring.

- Why Is LiFePO4 the Future of Forklift Batteries?

- What Are the Latest Innovations in LiFePO4 Forklift Battery Technology

- Why Are LiFePO4 Batteries Dominating Material Handling Markets?

- What Are the Latest Forklift Battery Regulations?

- Why Are Companies Switching to LiFePO4 Forklift Batteries?

- How Can You Stay Updated on Forklift Battery Technology Events?

What Innovations Are Driving LiFePO4 Adoption in Warehousing?

Smart battery management systems (BMS) now predict cell failures and optimize charge cycles via AI. Modular designs allow hot-swapping cells without shutting equipment. Wireless charging pads enable autonomous AGVs to recharge during tasks. Tesla’s Megapack-derived batteries now power entire fleets, while graphene-enhanced anodes boost charge rates to 15 minutes.

The integration of IoT sensors has revolutionized energy management in warehouses. These systems automatically adjust charging patterns based on shift schedules, reducing peak demand charges by 18-25%. Some advanced BMS solutions even interface with warehouse management software, coordinating battery usage with inventory movement patterns. Emerging fast-charging stations using silicon carbide technology can deliver 80% charge in under 10 minutes, effectively enabling 24/7 operation without battery swaps. Industry analysts project these innovations will drive 35% annual growth in LiFePO4 adoption through 2030.

“LiFePO4 isn’t just a battery upgrade—it’s a logistics revolution,” says Dr. Elena Torres, Energy Systems Lead at Redway. “Warehouses using these batteries report 20% faster throughput and 60% lower energy costs. With AI-driven BMS, we’re seeing lifespan predictions accurate to 98%, slashing unplanned downtime. The next leap? Solid-state LiFePO4 doubling energy density by 2027.”

FAQs

- How long do LiFePO4 batteries last in forklifts?

- Typically 8–10 years or 2,000–5,000 full cycles—3x longer than lead-acid. Proper BMS maintenance can extend this to 12 years.

- Are LiFePO4 batteries recyclable?

- Yes. Over 95% of LiFePO4 materials are recoverable. Redway’s closed-loop program repurposes used cells for solar storage.

- Do LiFePO4 batteries work in sub-zero temperatures?

- Yes. They operate at -30°C to 60°C without heaters. Capacity drops to 75% at -20°C but recovers fully when warmed.