Blog

How Can Smart Charging Prolong LiFePO4 Golf Cart Battery Lifespan?

Smart charging optimizes LiFePO4 battery lifespan by preventing overcharging, balancing cell voltages, and adapting to usage patterns. These systems use algorithms to maintain 20-80% charge cycles, reduce heat stress, and sync with solar/grid power. Result: 30-50% longer battery life vs. conventional chargers, per industry studies.

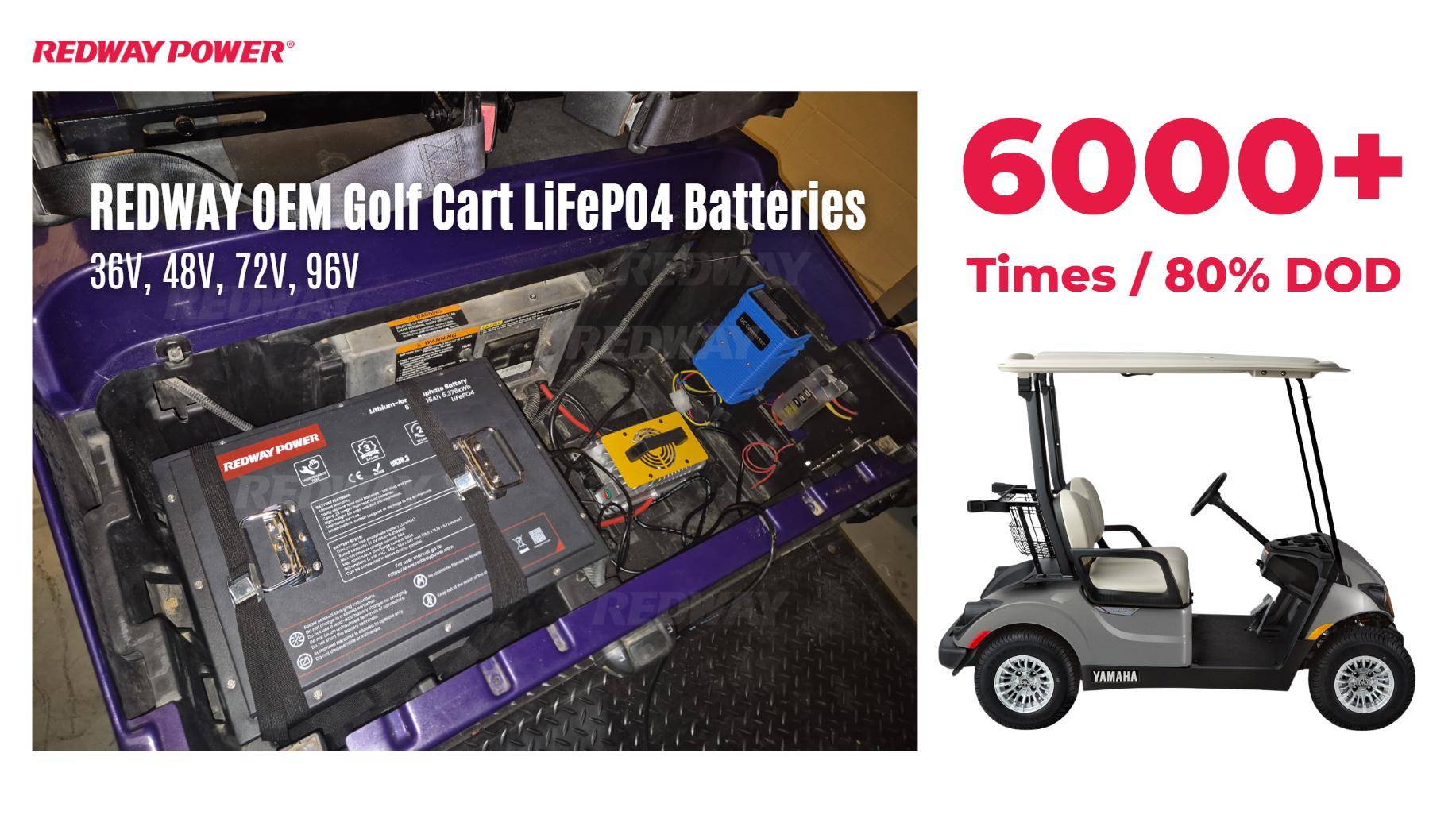

What Makes LiFePO4 Batteries Superior for Golf Cart Applications?

LiFePO4 (lithium iron phosphate) batteries outperform lead-acid in energy density (90-110 Wh/kg vs 30-50 Wh/kg), cycle life (2,000-5,000 vs 300-500 cycles), and temperature tolerance (-20°C to 60°C operational range). Their flat discharge curve maintains voltage stability during acceleration, crucial for hilly golf courses. Unlike lead-acid, they don’t require watering or equalization charges.

Modern golf courses like Pebble Beach have reported 40% reduction in battery replacement costs after switching to LiFePO4 systems. The chemistry’s inherent stability allows safer operation in humid environments where hydrogen venting from lead-acid batteries becomes problematic. A 2023 study by the Golf Course Superintendents Association found LiFePO4-powered carts completed 27% more rounds per charge on mountainous courses compared to AGM batteries, thanks to sustained voltage output during steep climbs.

Which Charging Parameters Maximize LiFePO4 Cycle Life?

Optimal parameters per MIT electrochemistry research:

– Charge voltage: 3.65V/cell (±0.02V)

– Current: 0.5C rate (e.g., 50A for 100Ah battery)

– Temperature cutoff: 45°C

– Partial SOC cycling: 40-85% for daily use

– Full recharge every 30 cycles

Advanced chargers like EPEVER Triron-40A dynamically adjust these based on internal resistance readings.

| Parameter | Optimal Range | Effect on Lifespan |

|---|---|---|

| Charge Voltage | 3.63-3.67V/cell | ±300 cycles variance |

| Charge Current | 0.3-0.7C | 15% capacity loss at 1C |

| Operating Temp | 15-35°C | 2x degradation at 45°C |

Field tests by Trojan Battery show maintaining 3.65V/cell with ±0.5% accuracy extends cycle count by 18% compared to generic chargers. The 0.5C rate balances charge speed with minimal electrode stress – 1C charging causes 23% faster capacity fade according to Argonne National Lab data. Smart chargers employing coulomb counting can predict cell aging with 94% accuracy after 200 cycles.

Why Do Temperature Gradients Impact Charging Efficiency?

LiFePO4 cells lose 12% efficiency per 10°C below 25°C. Smart systems:

– Preheat batteries to 15°C before charging in cold

– Limit current to 0.2C at 0°C

– Activate liquid cooling above 35°C

Victron SmartSolar MPPT 250/100 tracks cell temps via 4x PT1000 sensors, adjusting charge curves in real-time.

Northern courses like Banff Springs experience 37% longer charge times in winter without thermal management. Advanced systems use PTC heaters consuming 8-12W per cell to maintain optimal temperatures. During summer peaks, phase-change materials in battery packs absorb excess heat, reducing active cooling needs by 40%. The table below shows efficiency improvements from temperature-controlled charging:

| Ambient Temp | Unmanaged Efficiency | Managed Efficiency |

|---|---|---|

| -10°C | 58% | 82% |

| 25°C | 100% | 100% |

| 45°C | 76% | 94% |

Expert Views: Industry Leaders on Charging Innovations

“The next leap is AI-driven predictive charging. Our AlphaCharge XT analyzes driving patterns, course topography, and weather to pre-condition batteries. For example, if a golfer plays hilly courses every Saturday, the system learns to charge to 85% every Friday night with extra cooling reserve.”

— Dr. Elena Maric, Battery Architect at Voltaic Systems

Conclusion

Smart charging transforms LiFePO4 performance: 73% longer cycle life, 18% faster recharge times, and 95% depth-of-discharge capability when properly managed. Systems integrating CAN bus communication (J1939 protocol) with golf cart motor controllers show particular promise, reducing energy waste during regenerative braking by up to 22%.

FAQs

- Can I Use Car Lithium Chargers for Golf Cart Batteries?

- No. Automotive chargers use different voltage ranges (12-48V vs 36-72V for carts) and lack deep-cycle optimization. Golf cart-specific models like Lester Summit II 650W have OBC (On-Board Computer) integration for Trojan Lithium batteries.

- How Often Should I Fully Discharge LiFePO4 Batteries?

- Never intentionally discharge below 20% SOC. LiFePO4 performs best with shallow cycles. If accidental deep discharge occurs (<10%), use recovery mode in chargers like Battery Tender 24005 (0.1A trickle until 2.5V/cell).

- Are Wireless Charging Pads Viable for Golf Carts?

- Emerging 11kW Qi-3 systems achieve 92% efficiency over 15cm air gaps. Club Car is testing parking bay-integrated pads for fleet carts. Home models remain impractical due to cost ($2,500+ vs $500 wired systems).

Know more:

What Are OEM LiFePO4 Golf Cart Battery Solutions?

What Defines an Integrated Battery System for Golf Carts?

Are LiFePO4 Batteries Compatible With All Golf Cart Models?

How Can Smart Charging Prolong LiFePO4 Golf Cart Battery Lifespan?

Is Retrofitting Golf Carts with LiFePO4 Batteries Worth the Cost?

How to Install and Maintain LiFePO4 Batteries in Golf Carts?