Blog

How to Install and Maintain LiFePO4 Batteries in Golf Carts?

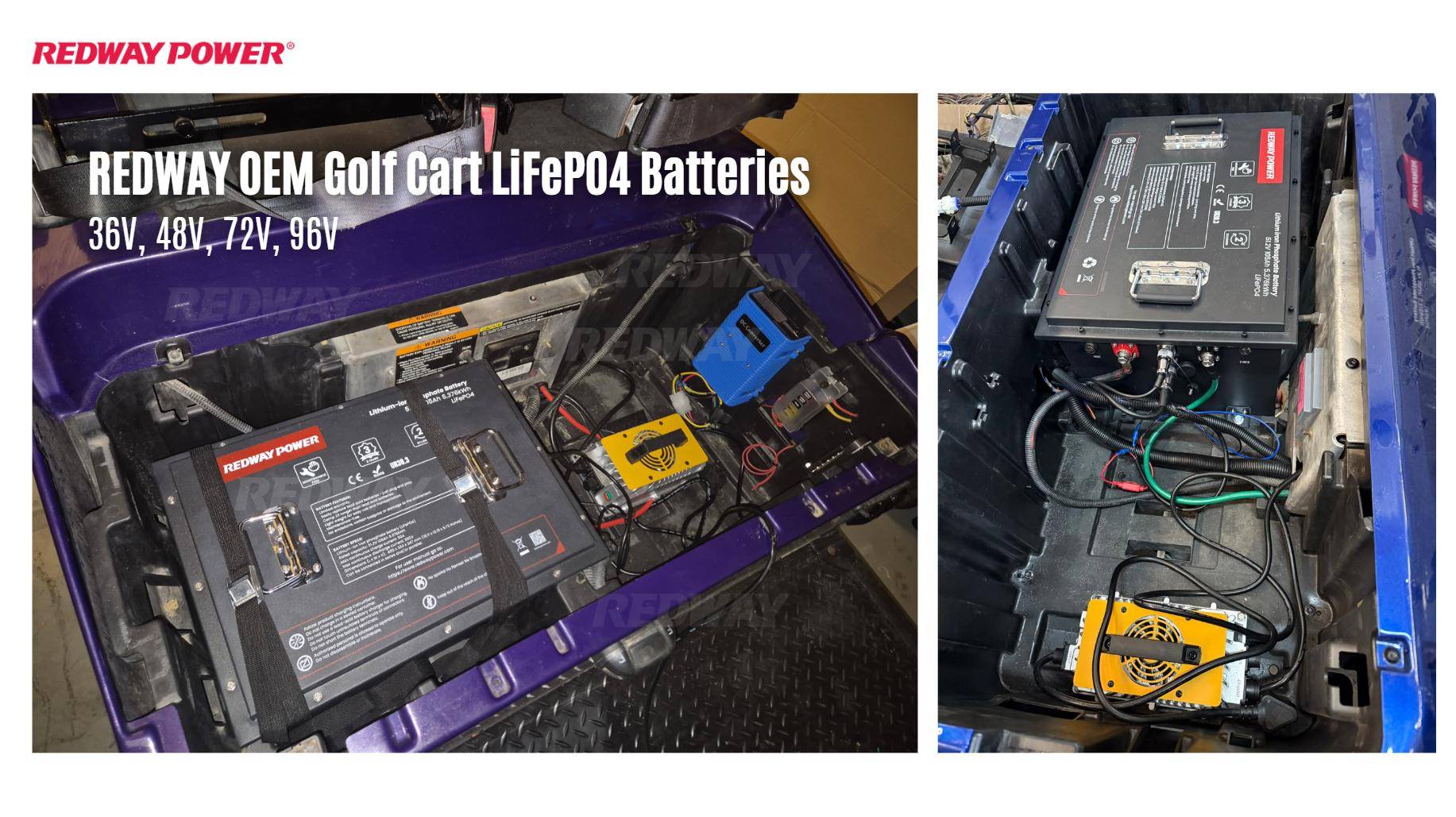

LiFePO4 (lithium iron phosphate) batteries offer longer lifespan, faster charging, and 50-70% lighter weight than lead-acid alternatives. They maintain consistent voltage output for 2,000+ cycles, require no water maintenance, and operate efficiently in 0°C to 45°C temperatures. Proper installation and monthly voltage checks optimize their 8-10 year service life.

What Are the Key Advantages of LiFePO4 Batteries for Golf Carts?

LiFePO4 batteries outperform traditional options with 95% depth of discharge capability versus 50% for lead-acid. They deliver 30% more torque for hill climbs, lose only 2% charge monthly when idle, and reduce total ownership costs by 40% despite higher upfront pricing. Built-in Battery Management Systems (BMS) prevent overcharging and thermal runaway.

Recent field studies demonstrate that golf courses using LiFePO4 batteries experience 18% faster round completion times due to consistent power delivery. The weight reduction allows for additional cargo capacity – a standard 48V pack weighs 28kg compared to 68kg for equivalent lead-acid systems. Manufacturers like Club Car now offer integrated battery monitoring through mobile apps, providing real-time data on state of charge and performance metrics.

How to Properly Install LiFePO4 Batteries in Golf Carts?

Disconnect existing batteries starting with negative terminals. Clean tray surfaces with baking soda solution to neutralize acid residue. Use anti-vibration pads and stainless steel mounting hardware (8-10mm bolts recommended). Maintain 15mm spacing between cells for airflow. Connect terminals in series using 4 AWG copper cables, applying dielectric grease to prevent corrosion. Initial charge to 14.6V before first use.

Which Maintenance Practices Extend LiFePO4 Battery Lifespan?

Perform monthly voltage checks (13.2-13.4V ideal for storage). Clean terminals quarterly with brass brush and isopropyl alcohol. Store at 50% charge in 15-25°C environments. Use only compatible 58.4V lithium-specific chargers. Rebalance cells annually using a 0.5C balancing charger. Avoid discharges below 10.8V per battery to prevent BMS lockout.

What Safety Protocols Prevent Lithium Battery Failures?

Install Class T fuses within 150mm of positive terminals. Use fire-resistant battery boxes with 1.5mm steel construction. Never exceed 60°C operating temperatures. Ground the system to chassis with 6 AWG wire. Follow UN38.3 transportation certification requirements. Thermal sensors should trigger automatic disconnect at 70°C. Annual infrared scans detect loose connections before failure.

| Safety Component | Specification | Installation Tip |

|---|---|---|

| Class T Fuse | 20kA Interrupt Rating | Mount within 6″ of battery |

| Thermal Sensor | Range: -40°C to 125°C | Attach to cell midpoint |

| Battery Box | Ventilation: 25cm² openings | Use neoprene gaskets |

Advanced installations should incorporate redundant disconnect systems – combining magnetic circuit breakers with manual cutoff switches. Recent UL certifications now require dual-stage temperature monitoring that samples both cell surface and terminal temperatures every 15 seconds.

Know more:

What Are OEM LiFePO4 Golf Cart Battery Solutions?

What Defines an Integrated Battery System for Golf Carts?

Are LiFePO4 Batteries Compatible With All Golf Cart Models?

How Can Smart Charging Prolong LiFePO4 Golf Cart Battery Lifespan?

Is Retrofitting Golf Carts with LiFePO4 Batteries Worth the Cost?

How to Install and Maintain LiFePO4 Batteries in Golf Carts?

How to Troubleshoot Common LiFePO4 Performance Issues?

For voltage drops: Check cell balance (max 0.2V deviation). If BMS disconnects, reset using 58.4V charger. Reduced capacity indicates needed calibration – discharge fully then recharge. Error codes: E01 (overvoltage) requires charger verification; E04 (low temp) needs ambient above -20°C. Always use lithium-rated multimeters for diagnostics.

What Environmental Benefits Do LiFePO4 Systems Provide?

LiFePO4 contains no toxic lead or cadmium, with 90% recyclability. They reduce energy waste through 98% charge efficiency versus 70-85% in lead-acid. A 100Ah battery prevents 150kg of CO2 emissions annually. Solar compatibility enables off-grid charging, with 25-year lifespan matching PV panel durability.

“Modern LiFePO4 systems now integrate IoT monitoring – our Pro Series tracks 18 parameters in real time via Bluetooth. Golf courses using networked batteries reduce energy costs 22% through smart load balancing. The next breakthrough? Solid-state lithium designs arriving 2026-2027 will boost energy density 40% while eliminating thermal risks.”

– Dr. Elena Voss, Chief Battery Engineer at PowerDrive Technologies (15 years in EV energy systems)

FAQs

- Can I use my existing lead-acid charger?

- No – lithium batteries require constant current/constant voltage (CC/CV) chargers with precise 58.4V cutoff. Using lead-acid chargers risks overcharging and permanent capacity loss.

- How cold is too cold for operation?

- LiFePO4 batteries shouldn’t charge below 0°C (32°F) but can discharge to -20°C (-4°F). For winter storage, keep at 30-50% charge in frost-free environments.

- Are swollen batteries dangerous?

- Minor swelling indicates cell imbalance – stop using immediately. LiFePO4 doesn’t experience thermal runaway like other lithium types, but compromised cells should be replaced by certified technicians.